About Transportation & Automotive Parts Making Machine

We provide advanced roll forming solutions for the transportation sector, producing high-strength, lightweight structural components that meet stringent safety and performance standards. Our lines integrate advanced processes like in-line welding and punching to manufacture complex profiles for automotive, shipping, and rail applications with exceptional precision.

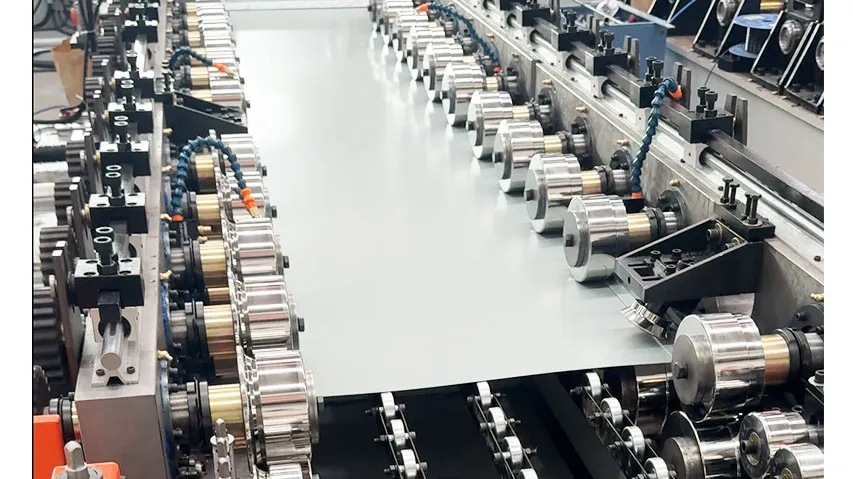

High-Precision Roll Forming Lines for Ship Interior Panel

Our specialized lines produce A-type and C-type panels for ship interiors with unparalleled precision. Featuring automatic material thickness adjustment, our systems control joint gaps and dimensions to within ±0.2mm, meeting the demanding fit-and-finish requirements for marine construction and breaking reliance on imported machinery.

Auto Ship Panels Roll Forming Production Process

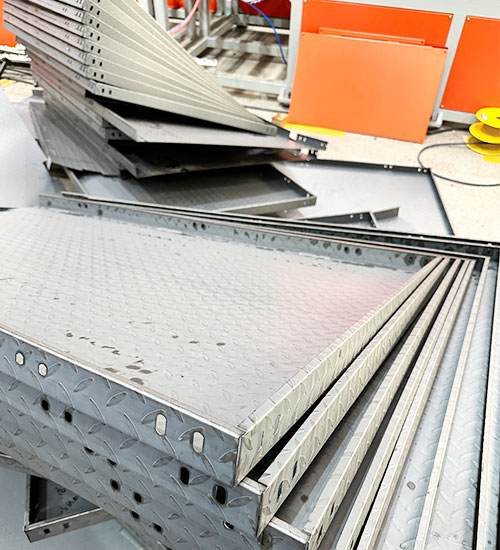

Ship panels Production Cases For Factory

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for ship panels. Here is a showcase of customizations we have made for ship panels factories.

Why Choose ARMDAX Roll Forming Machine

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

Precision Leveling Machine

Our precision leveling machine eliminates internal stresses and ensures consistently flat steel plates before roll forming—critical for seamless ship panel production. By removing waves and camber, the leveler guarantees uniform material entry into the roll forming line, resulting in precise profiles and smooth surfaces. Integrated leveling minimizes rework, reduces scrap, and accelerates the entire production process for large-scale shipbuilding projects. Ideal for shipyards and marine manufacturers prioritizing precision, durability, and efficiency.

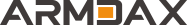

Conveyor belt with positioning

ARMDAX conveyor belt with automated positioning ensures ship panels are precisely aligned at every stage of roll forming, eliminating misalignment and ensuring consistent quality. Fully synchronized with the roll forming line, it enables smooth transitions between processes while maintaining perfect panel orientation for complex profiles. Ideal for shipyards seeking to enhance precision, speed, and reliability in panel production.

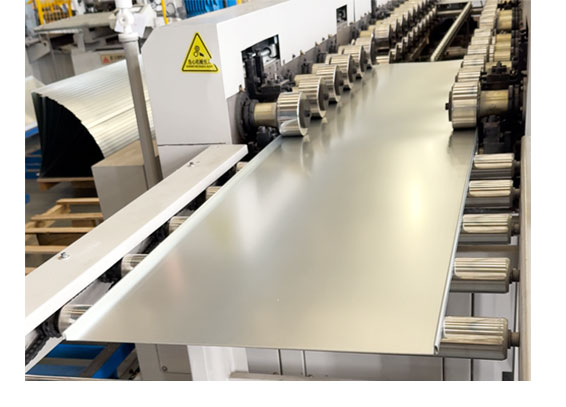

Advanced Roll Forming System

Continuous High-Speed Forming, Produce ship panel profiles up to 30 meters/minute, Maintain ±0.2mm tolerance across full panel length. Perfectly uniform panel sections, eliminate welding distortion, consistent curvature for hull assembly, 60% faster than traditional methods . Reduce labor costs by 50%, Minimal material waste. Perfect for modern shipyards building commercial vessels and offshore structures.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: What quality control standards does ARMDAX follow?

A:

ARMDAX follows strict quality control procedures, including raw material inspection, CNC machining accuracy checks, trial production testing, and pre-shipment inspection to ensure each roll forming machine meets international export standards.

Q: What is your after-sales repair policy about cold roll forming machines?

A:

We provide a one-year warranty for the entire machine. For key components such as the main unit, servo motors, and CNC controllers—excluding consumable parts (tools) from warranty coverage—if any non-human-caused malfunction occurs, we will immediately ship replacement parts free of charge via DHL/FedEx.

Q: What is the maximum material thickness and width your roll forming machines can handle?

A:

ARMDAX roll forming machines are built to handle a wide range. Typically, we work with material thicknesses from 0.2mm to 5 mm and coil widths can be adjustable. However, specific capabilities depend on the profile design and material strength. Our engineers will provide exact specifications after reviewing your requirements.

Q: Do you provide installation and training?

A:

Yes, we provide detailed installation manuals and video guides. We also offer optional overseas engineer dispatch for on-site installation and training, with all costs (travel, accommodation) quoted separately.