Your Roll Forming Machine Custom Expert

In an increasingly competitive manufacturing industry , how can we produce higher quality products with lower costs and faster speeds? Armdax roll forming machine is the ultimate answer to this question. Roll forming is a widely used metal forming process, which is extensively applied in various industries and can produce complex profiles with high precision and efficiency.

Advantage

What Can A Roll Forming Machine help you

Slash Your Labor Costs

Through Automation

Our fully automated lines operate continuously from coil to finished product, requiring only a single operator to oversee the entire process. This allows you to reallocate your skilled workforce to higher-value tasks and significantly mitigate the impact of labor shortages and rising wage costs.

Maintain extremely high

precision and efficiency

Armdax automated production line integrates efficient servo drive and precise flying saw cutting, achieving a line speed of up to 25-30 meters per minute. It employs a high-precision gear transmission system and precision-ground forming rollers, ensuring that the dimensional tolerance of the product cross-section is stably controlled within ±0.3mm, with strong stability.

Adapt to Market

Demands in Minutes

Our intelligent control system with its "one-key switch" function allows you to change product specifications, hole patterns, and lengths directly from the touch screen. This drastically reduces changeover downtime, empowering you to profitably handle diverse, small-batch orders with extreme agility.

Cut Material Scrap

Rate to Below 3%

By utilizing exact-width coils in a continuous process, our lines eliminate the significant skeletal waste common in traditional sheet processing. This optimizes your raw material usage, turning material cost savings directly into increased profit margins.

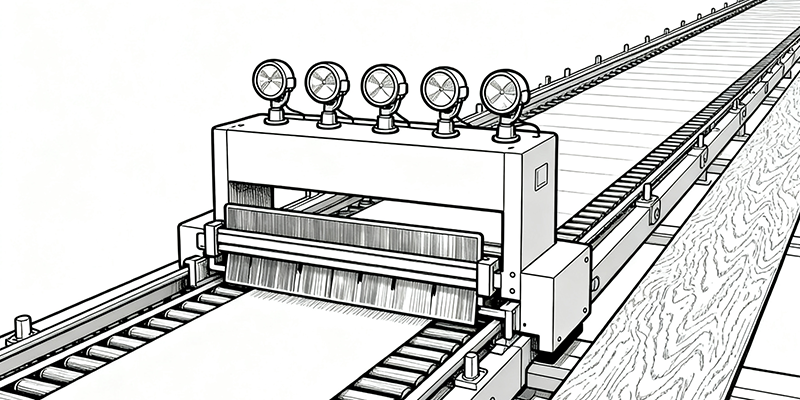

The ARMDAX Process

From Coil to Component in One Continuous Flow

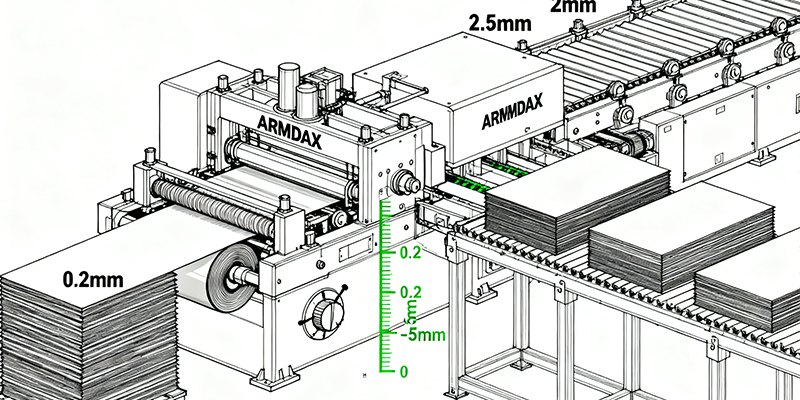

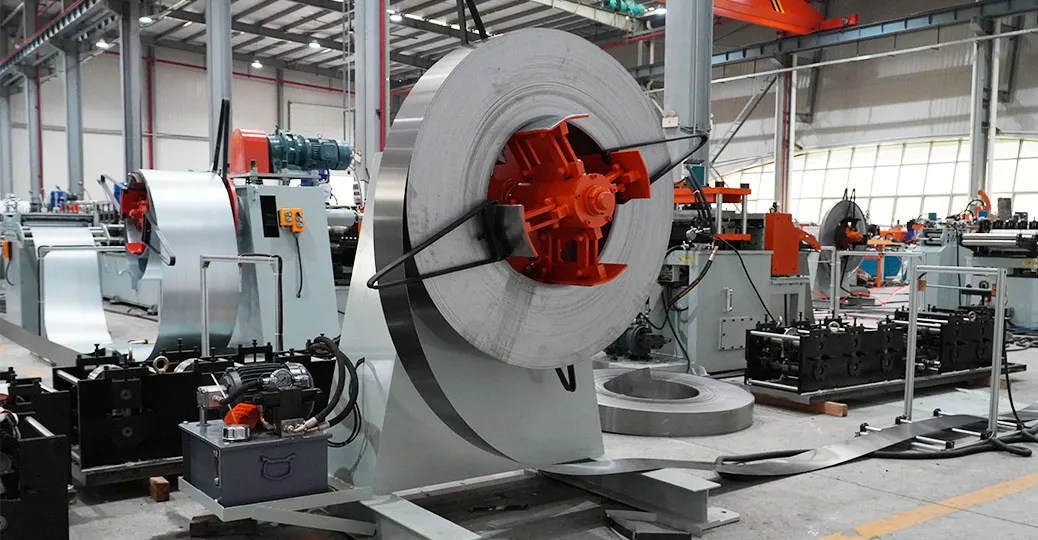

The process begins with perfect preparation. Our systems uncoil and precisely level the raw material, eliminating stress and ensuring a flat, consistent strip—the foundation for flawless finished parts.

Uncoiling & Leveling

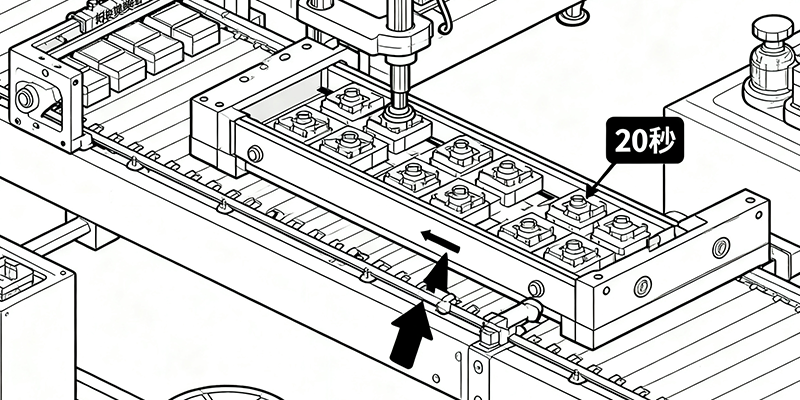

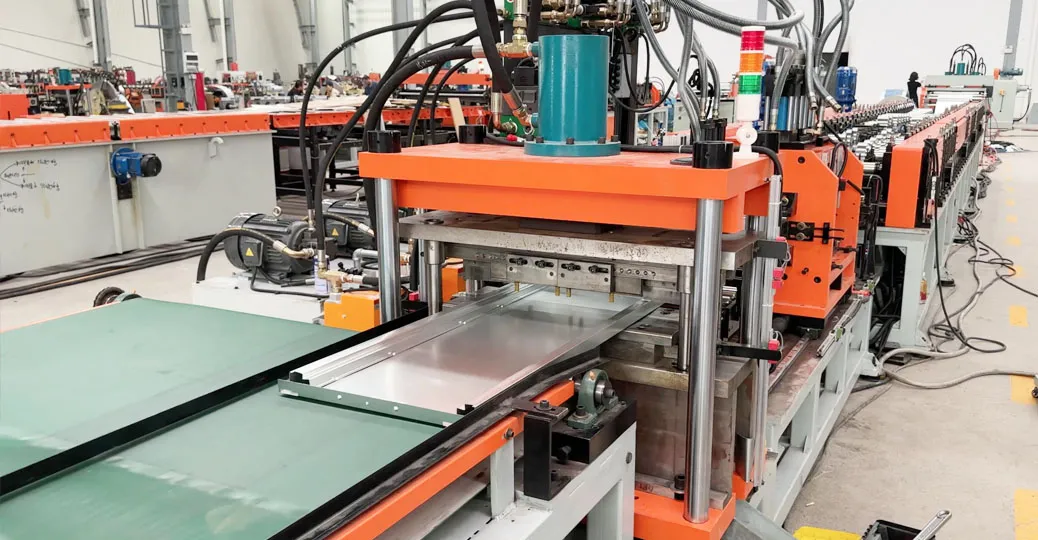

High-precision servo feeding delivers the material to the integrated punching system. Execute complex hole patterns and notches with exceptional accuracy, all controlled via a user-friendly touch screen for one-touch specification changes.

Servo Feeding & Punching

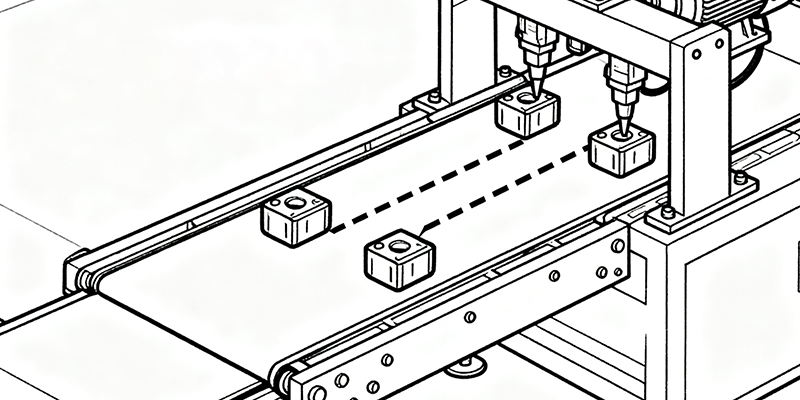

This is the heart of our system. A series of meticulously engineered rollers gradually bend the metal into your exact profile. This cold forming process enhances material strength while maintaining tight dimensional tolerances.

Precision Roll Forming

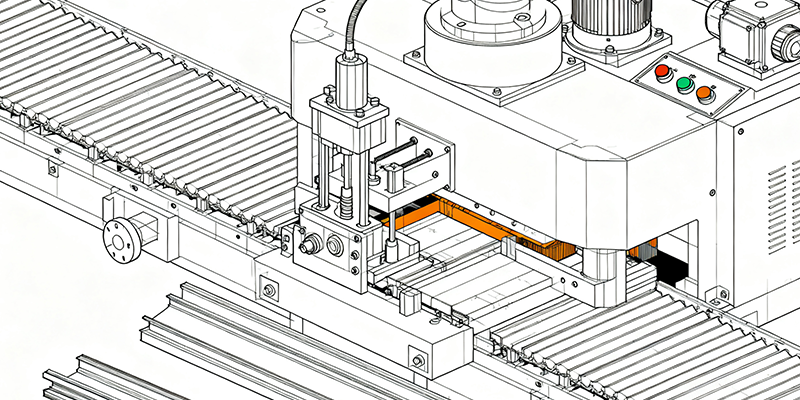

The process begins with perfect preparation. Our systems uncoil and precisely level the raw material, eliminating stress and ensuring a flat, consistent strip—the foundation for flawless finished parts.

Automated Cutting & Finishing

Technical specifications

Metal

Product Material

0.2-5mm Optional

Material Thickness

Servo Adjustable

Product Width Range

±0.3mm

Margin of error

Yaskawa Servo Motor Driven

Drive System

Up to 35m/min

Form speed

Mitsubishi PLC or other Optional

Control System

Cr12MoV

Roller material

Servo Motor

Schneider,Siemens, Yaskawa .etc

Solutions

Custom Solutions for Your Industry

R&D manufacturing

Reliability by Design: The ARMDAX Quality Standard

Precision Manufacturing

Innovation Driven by R&D

Uncompromising Component Quality

FAQ

Q: Do you provide installation and training?

Yes, we provide detailed installation manuals and video guides. We also offer optional overseas engineer dispatch for on-site installation and training, with all costs (travel, accommodation) quoted separately.

Q: How much does a roll forming machine cost ?

Different industries and different product sizes will affect the price of the machine. We customize solutions based on the your drawings and then calculate the price. We have a professional set of customization and production processes. Do you want to know the price of a roll forming machine , click this blogs maybe can help you understand.

Q: Can I visit your factory?

Absolutely, we warmly welcome you to visit our factory. Please let us know your preferred dates, and we will make the necessary arrangements to accommodate your visit to ARMDAX , and show our modern and intelligent cold roll forming machine factory. Contact us Now !

Contact Us

discuss your project and discover how a custom ARMDAX solution can redefine your production efficiency.