About Racking & Shelving Machine

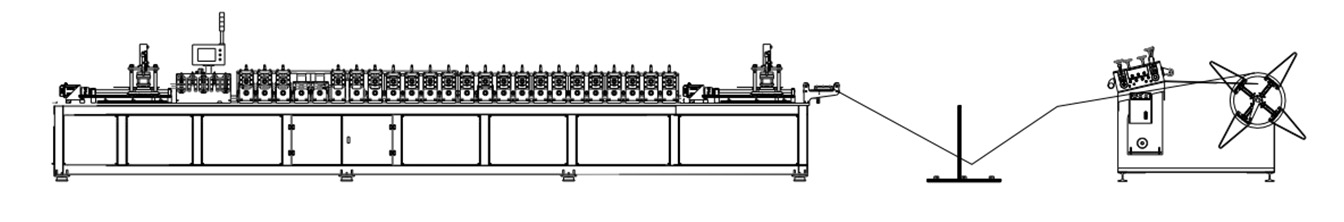

ARMDAX design and manufacture turnkey roll forming lines for manufacturing shelf panels , rack uprights,P-beams and Bracings. Our systems integrate Uncoiling feeding →leveling →punching system →roll forming-automatic cutting - flanging - finished product , to produce a wide range of profiles, from heavy-duty industrial racks to retail shelving. Achieve high-speed production, exceptional precision, and rapid changeovers with robust, automated solutions engineered for maximum uptime and profitability.

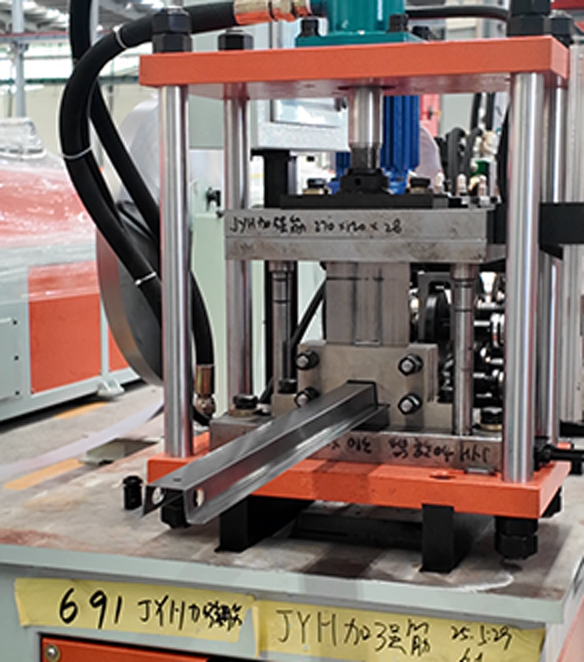

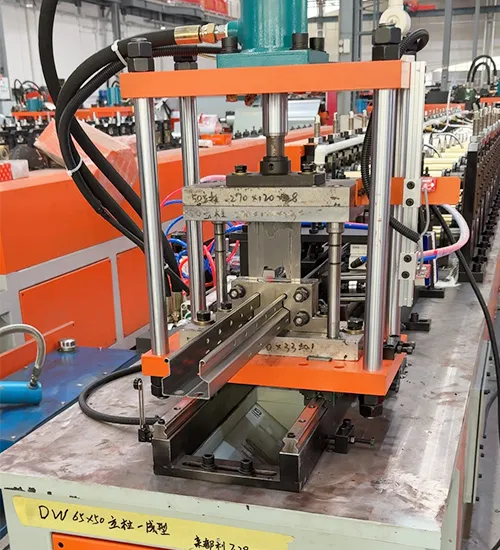

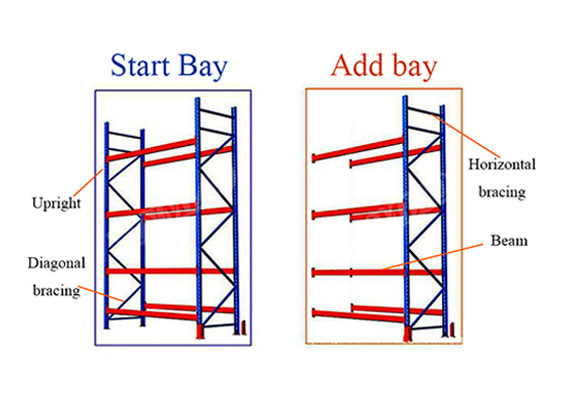

High-Speed Production Lines for Racking System Bracing

Efficiently produce horizontal bracing components and stiffener with our dedicated roll forming lines. Optimized for high-speed, continuous production of C-profiles and other shapes, these systems ensure dimensional accuracy for perfect fitment. Achieve stable, fast, and precise mass production for all your racking system reinforcement needs.

Automated Cold Roll Forming Line Process

Related Side Bracing Product Cases Display

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for side-bracing-stiffeners. Here is a showcase of shelf customizations we have made for shelving factories.

Metal Sheet Forming Excellence with ARMDAX

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

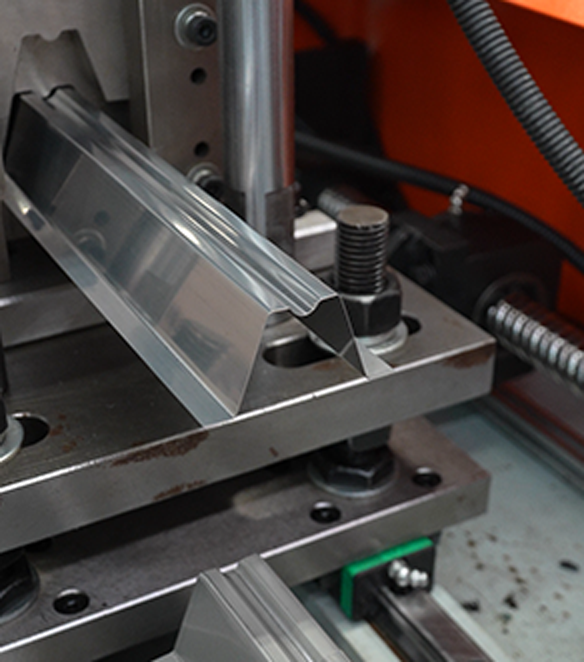

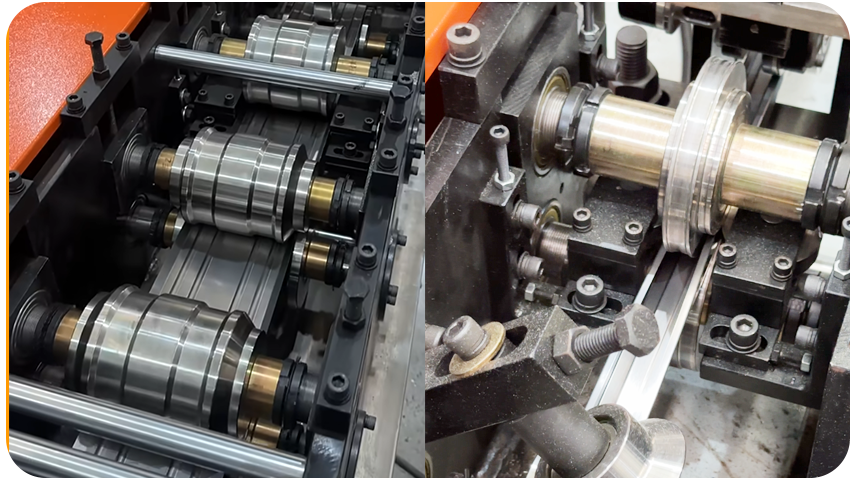

Precision Roll Forming

This is the heart of our system. A series of meticulously engineered rollers gradually bend the metal into your exact profile. This cold forming process enhances material strength while maintaining tight dimensional tolerances.

The Strength of Welded Side Bracing

Our welded side bracing delivers uncompromising strength and durability. Welding creates a permanent, monolithic structure that effectively resists lateral forces and prevents rack sway. Each brace is accurately positioned and welded, ensuring perfect geometry and alignment for easy installation.The welded joint withstands the test of time, outperforming mechanical fasteners in demanding high-capacity environments.

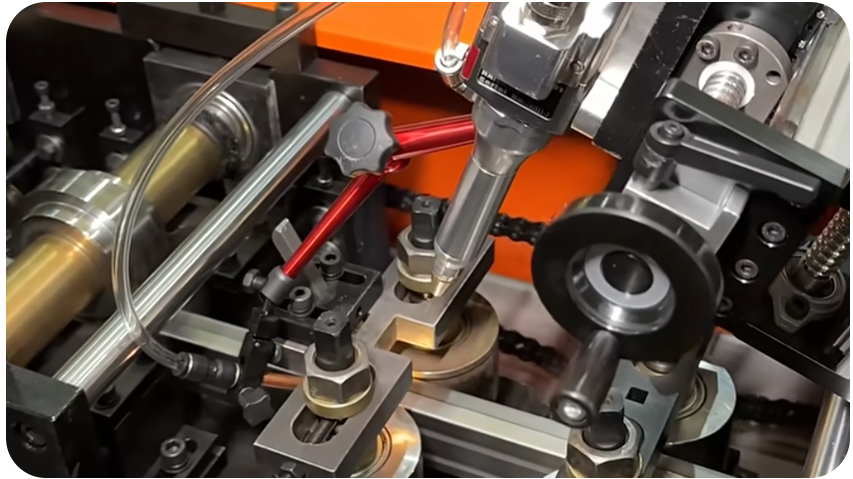

Flying cutting Technology

As the Side bracing is continuously formed, a synchronized flying cut-off saw delivers a perfectly square, burr-free cut without stopping the line. This guarantees dimensional accuracy and a flawless finish. Immediately after cutting, the aquare is notched and formed to seamlessly snap-lock onto the upright. This creates a rock-solid connection that's fast to assemble and incredibly strong.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: Can ARMDAX customize roll forming machines for storage racking profiles?

A:

Yes. ARMDAX provides customized racking roll forming machines based on load requirements, profile thickness, hole patterns, and international racking standards, ensuring high precision and repeatability.

Q: What types of racking roll forming machines does ARMDAX supply?

A:

ARMDAX supplies heavy-duty racking roll forming machines for pallet racking, selective racking, drive-in racking, and warehouse storage systems, with optional inline punching and servo cutting systems.

Q: What is your after-sales repair policy about cold roll forming machines?

A:

We provide a one-year warranty for the entire machine. For key components such as the main unit, servo motors, and CNC controllers—excluding consumable parts (tools) from warranty coverage—if any non-human-caused malfunction occurs, we will immediately ship replacement parts free of charge via DHL/FedEx.

Q: What is the maximum material thickness and width your roll forming machines can handle?

A:

ARMDAX roll forming machines are built to handle a wide range. Typically, we work with material thicknesses from 0.2mm to 5 mm and coil widths can be adjustable. However, specific capabilities depend on the profile design and material strength. Our engineers will provide exact specifications after reviewing your requirements.