ARMDAX CNC Panel Bender : Precision Power for Demanding Metal Fabrication

ARMDAX CNC panel bender is a high-precision, fully automated sheet metal processing system designed for high-volume production and stringent quality requirements in modern manufacturing. Equipped with an advanced servo control system and intelligent algorithms, it enables rapid and accurate metal plate forming, serving as a core solution for smart workshop transformation.

Advantage

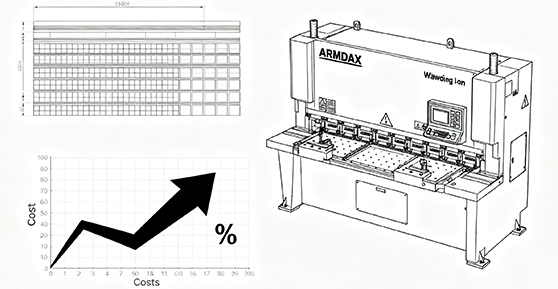

Your Return on Investment, Quantified

High Efficiency

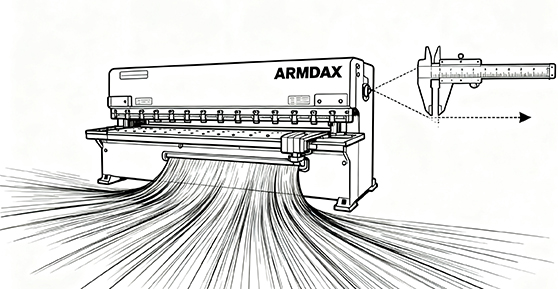

Bending cycles of 0.2 s/bend, with efficiency 3-5 times higher than traditional equipment.

High-precision control

±0.01mm repeat positioning accuracy ensures product consistency.

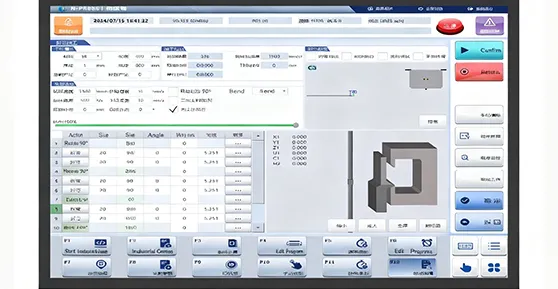

Easy Control

Integrated EtherCAT high-speed bus, faster programming, and simpler operation.

High Return Output

Efficient production cycles and automation capabilities ensure maximum productivity and profitability.

ARMDAX Bending Machines

Fully Automated Sheet Metal Processing System

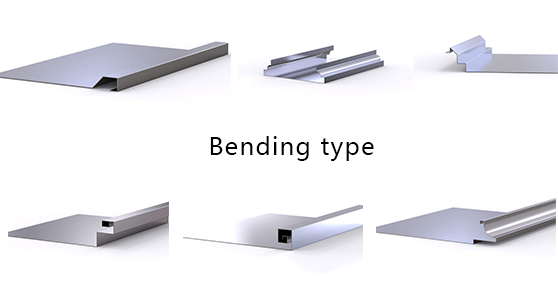

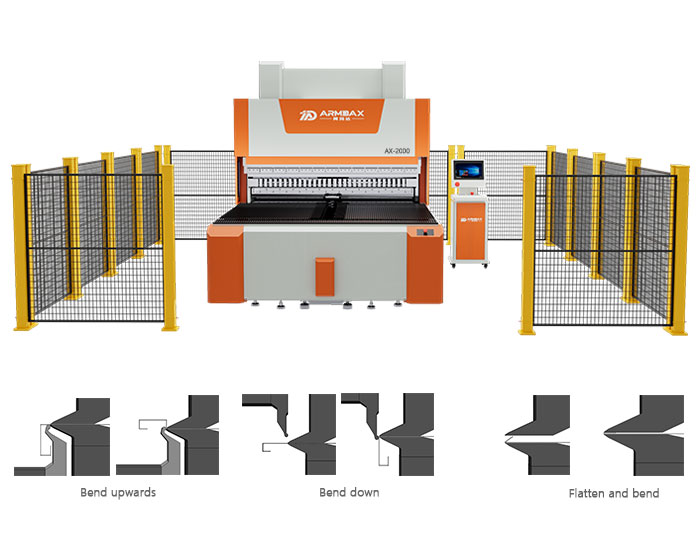

AX-Series: Versatile Tooling System, Adapts flexibly to diverse bending and forming requirements, meeting your most complex production demands.

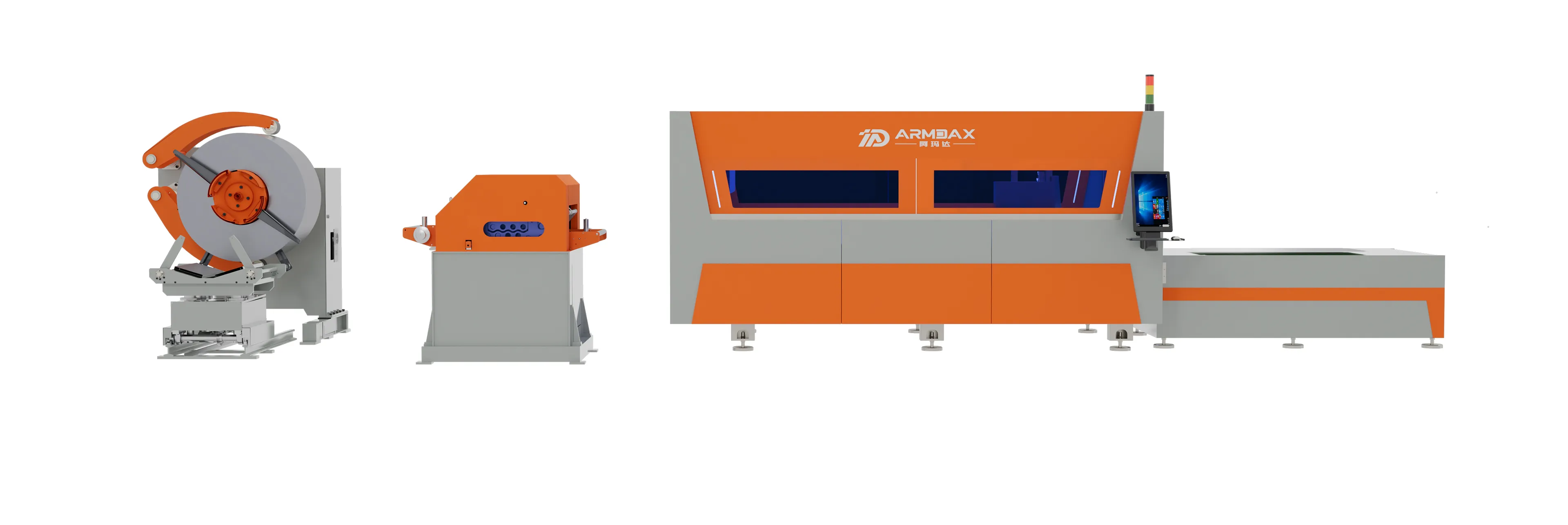

Suction Cup Panel Bending Machine

AP-Series: Integrated with EtherCAT high-speed bus technology. As a leading industrial Ethernet protocol, EtherCAT delivers exceptional performance and rapid response through its highly flexible topology.

Pressure Arm Type Plate Bending Machine

AF-Series: A flexible, panel-type bending machine specifically engineered for upward flanging processes. It delivers a more economical investment and higher production rates, making it the ideal choice for workpieces such as cabinets, filing cabinets, and metal door panels.

Sheet Folding Machine

AD-Series: Electric Servo Press Brake integrates cuting-edge drive technology with rigid structural design, equipped with an advanceddual-servo drive system and high-load-capacity ball screw and guideway structure, delivering exceptional motion performance andprocessing eficiency that surpass traditional hydrauic press brakes.

Electric Servo Press Brake

Technical specifications

Metal

Product Material

Iron plate 2mm/ stainless steel 1.5mm/ aluminum plate 3mm.

Bending Thickness

Up to 3000mm

Bend Width

170mm for standard and can be raised

Bend Height

250mm*120mm

Minimum Forming Size

0-180°

Bending Angle

0.2sec/bend

Fastest Bend Speed

12-Axis

Number of Axes

SL300-PX Brand: NiuLanKe

Numerical Control System

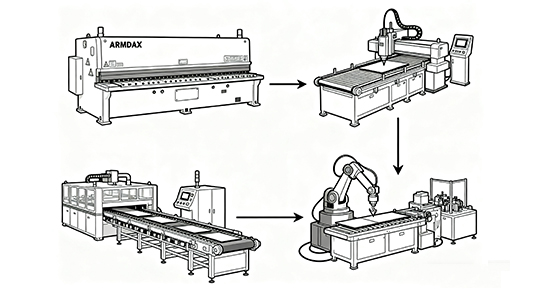

Solutions

Armdax Strong and Smart Automated production line

Smart manufacturing

Why Choose ARMDAX Bending Machine ?

20+ Years of Expertise

Global Support Network

Proven Reliability

FAQ

Q: What materials can your bending machine handle?

Armdax bending machines are capable of bending a variety of materials including iron, stainless steel, aluminum

Q: What's your CNC Panel benders different with other brands ?

Armdax CNC Panel benders equipped with advanced servo control systems and intelligent algorithms, it enables rapid and accurate metal plate forming, serving as a core solution for smart workshop transformation.

Q: What is the difference between a press-arm bending center and a suction cup bending center?

In short, both bending centers bend equally well—the real difference is how they hold the sheet. The press-arm type clamps sheets from top and bottom, so it can handle punched, dented, or odd-shaped sheets without slipping. Great for thick, large, or pre-punched plates.The suction type uses vacuum cups to pick, move, and spin sheets 360° quickly. Perfect when you need fast loading and flexible positioning.

Contact Us

discuss your project and discover how a custom ARMDAX solution can redefine your production efficiency.