R&D Capabilities

Innovation Driven by an Expert R&D Team

As a cold roll forming supplier with deep experience, Our commitment to innovation is embodied by our 30+ person professional R&D team—a convergence of experts in mechanical engineering, mold design, and automation control. The core of this team is comprised of seasoned specialists, each with more than a decade of deep industry experience, capable of executing projects of any scale across numerous sectors.

We operate a complete technical "closed-loop" development process. Using professional software such as SolidWorks and AutoCAD for 3D modeling, we couple design with advanced forming simulation and validation. This rigorous digital-first approach ensures that every solution is virtually tested, optimized, and proven before a single piece of steel is cut.

This methodology mitigates risk, accelerates deployment, and ensures the final solution precisely meets your production requirements, delivering a higher return on investment and a lower total cost of ownership.

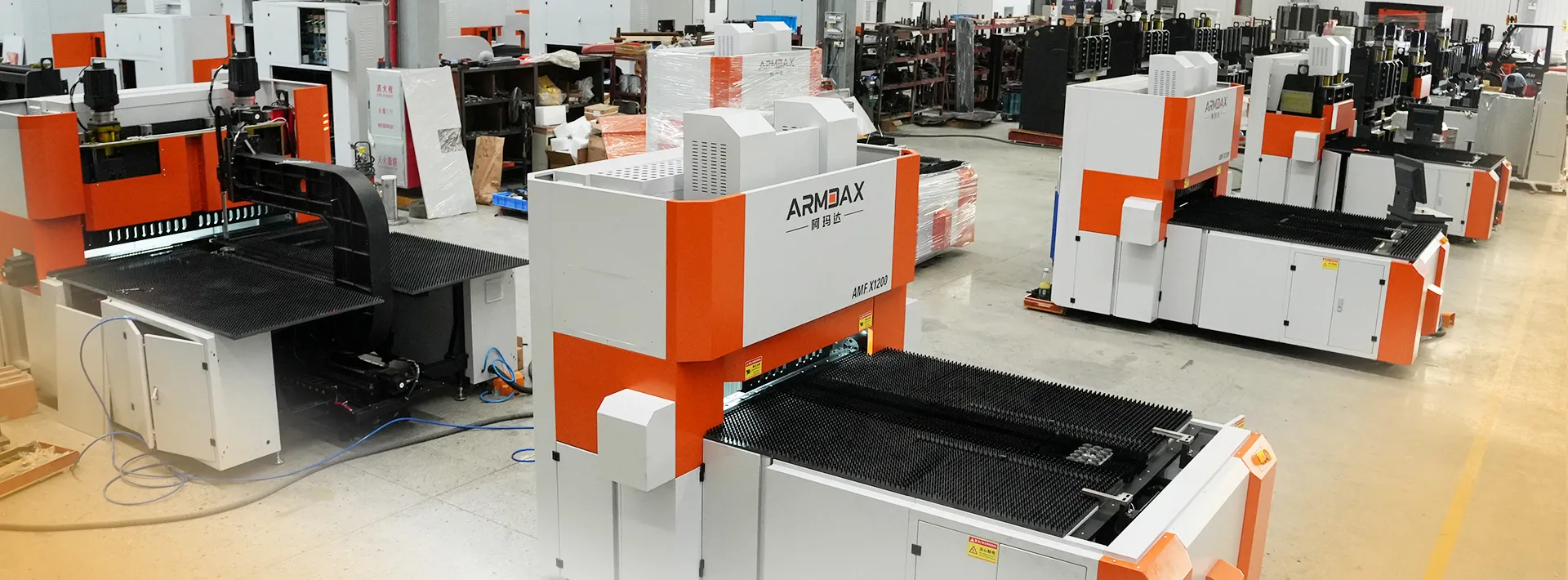

Production Capacity

An Integrated, Roll Forming Intelligent Manufacturing Powerhouse

We have engineered a fully integrated, intelligent production base that grants us absolute control over every stage of manufacturing. Our facilities include a dedicated General Assembly Plant, a Frame Welding Plant, and a Precision Parts Processing Plant, occupying a total area of over 20,000 square meters.

Within these walls, we operate a suite of world-class machining equipment, including Japanese Takisawa CNC lathes, DMG MORI (Demasi) machining centers, and Haitian CNC gantry machines. This advanced infrastructure empowers us to achieve what few can: the complete, in-house production of all core components. For our clients, this vertical integration translates directly into unparalleled benefits:

absolute mastery over quality control, guaranteed material integrity, predictable production timelines, and insulation from the volatility of external supply chains. Choosing Amada means choosing proven manufacturing quality and efficiency.

Quality Control

Strict Quality Control of The Rolling Forming Manufacturing

Quality is not just a final check; it is engineered into our entire project lifecycle. Our systematic approach ensures excellence from the initial consultation to final delivery and beyond.

Needs Analysis

We begin by thoroughly collecting your product requirements, including material type, thickness, and profile drawings, to understand your precise needs

Custom Design

Our roll forming experts create a detailed technical plan and design, tailored to your specific industry and product application.

Mechanical Design & Review

The design undergoes rigorous 3D modeling and virtual simulation testing to ensure project success before manufacturing begins.

Mechanical Design & Review

All manufacturing is conducted in-house under strict quality control standards, using advanced production technology.

Factory Acceptance Test (FAT)

Before shipment, your equipment is tested at our facility with your actual materials to ensure it meets all sample requirements and performance benchmarks.

Component Excellence

We reinforce our quality commitment by using internationally renowned brands for all key components, ensuring high performance and durability.

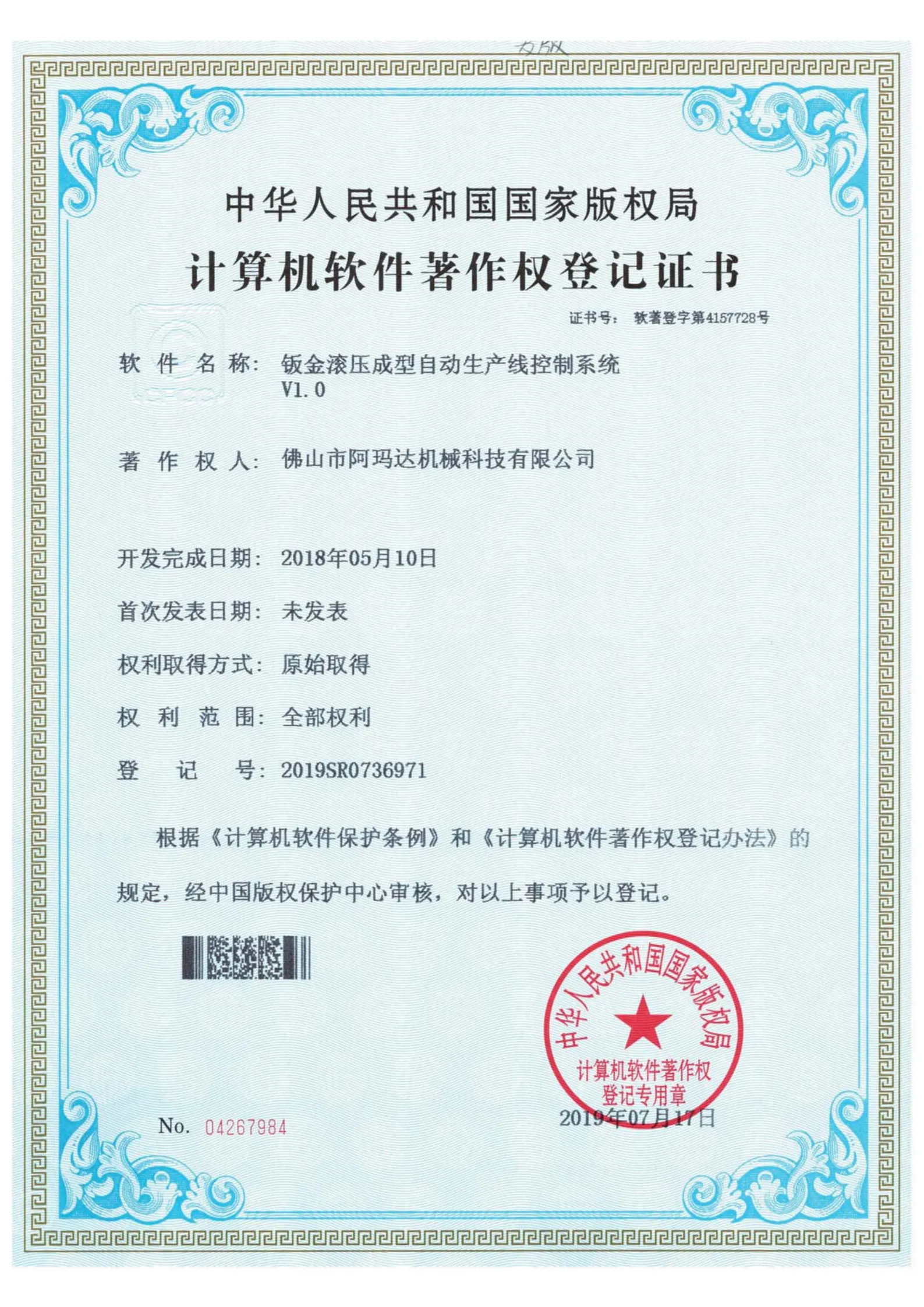

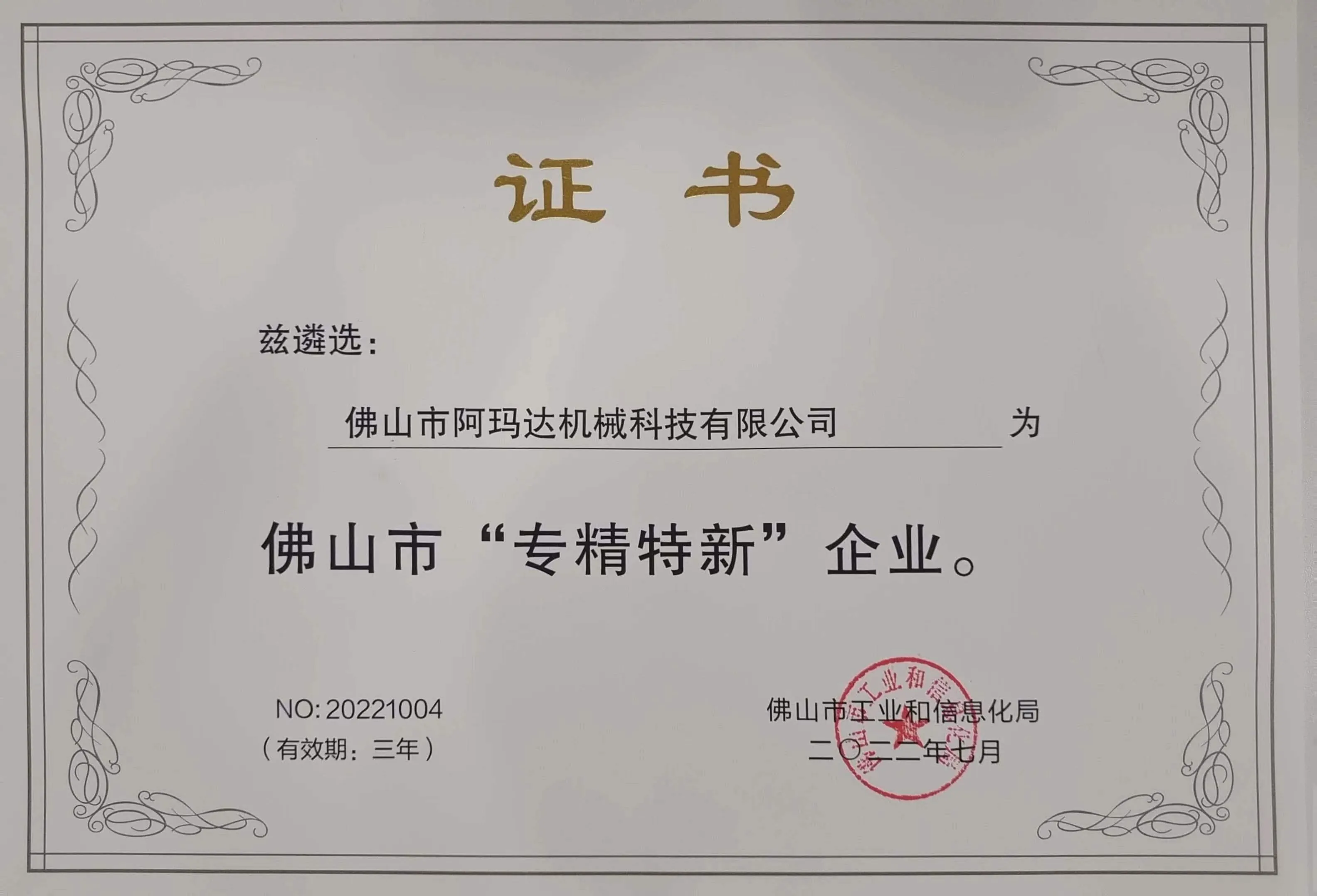

Quality Certification

Certified Excellence and Proven Innovation