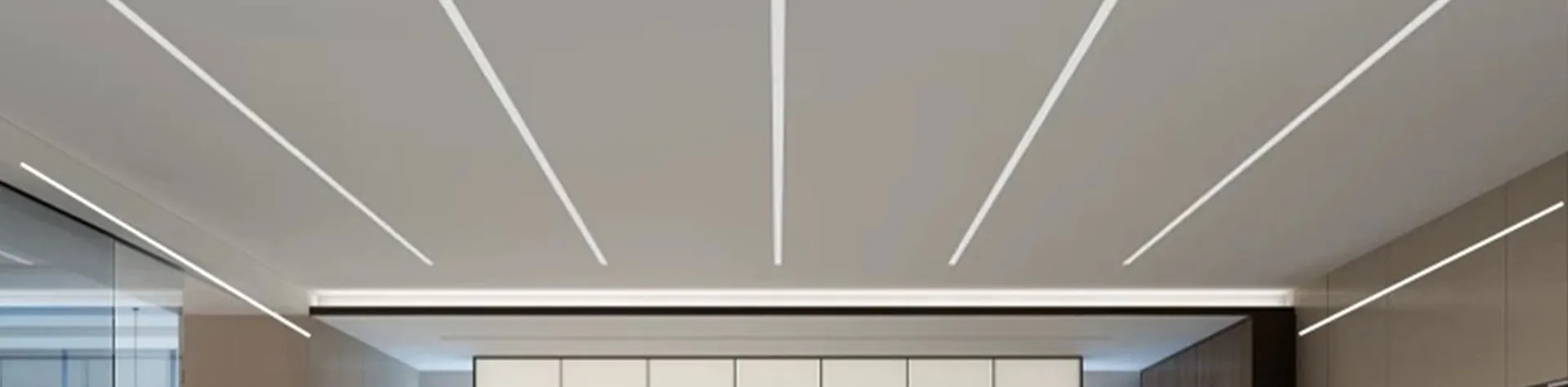

About LED Light Fixture Manufacturing

We deliver automated roll forming lines that meet the high aesthetic and functional standards of the LED light fixture industries. Our systems meeting key surface requirements for fluorescent light grooves and lampshades. producing components with flawless surfaces, tight tolerances, and the structural integrity required for high-end consumer goods.

Top Forming Solutions for LED Aluminum Channel Industry

We deliver automated roll forming lines that meet the high aesthetic and functional standards of the LED aluminum channel industries. Our systems handle aluminum and pre-finished materials with care, producing components with flawless surfaces, tight tolerances, and the structural integrity required for high-end home renovation demand.

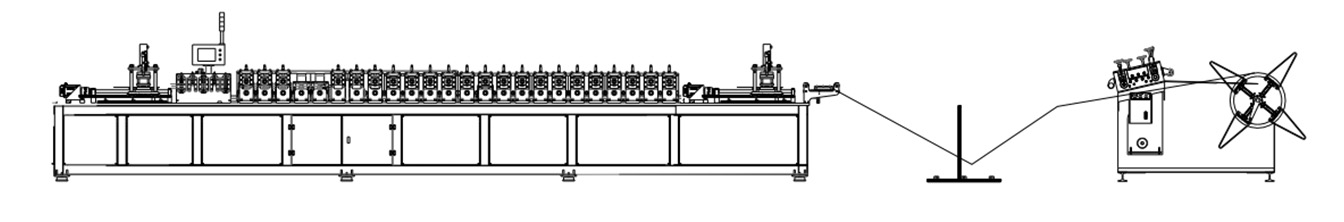

Auto Cold Roll Forming Production Process

Show the LED Aluminum Profiles Cases

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for LED aluminum channels. Here is a showcase of customizations we have made for LED Aluminum profiles factories.

Precision Engineering, Powered by ARMDAX.

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

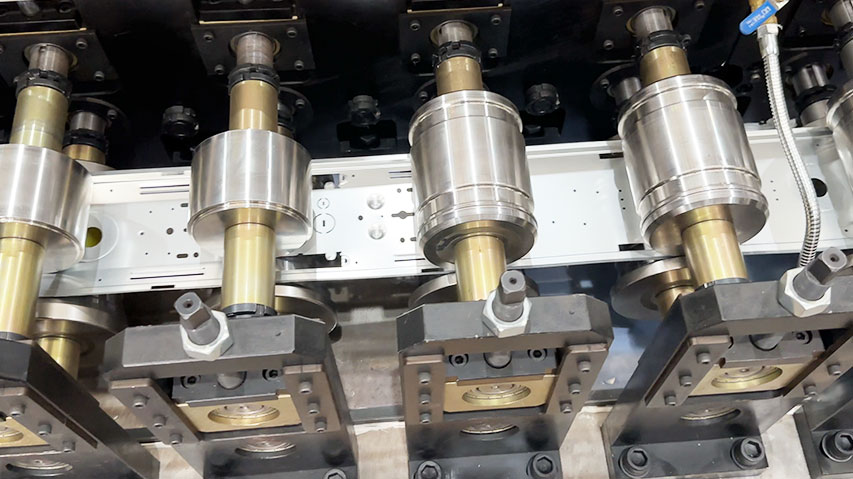

Armdax Hydraulic PunchingSystem

Armdax punch precise holes for clips and connectors directly in the forming process. Eliminate costly secondary operations. Hydraulic force delivers clean, burr-free holes in heavy-duty steel, ensuring perfect structural integrity. And Easily adapt punching patterns for different shelf models with quick tooling changes, which perfect for custom LED aluminum channels and applicable to porous production.

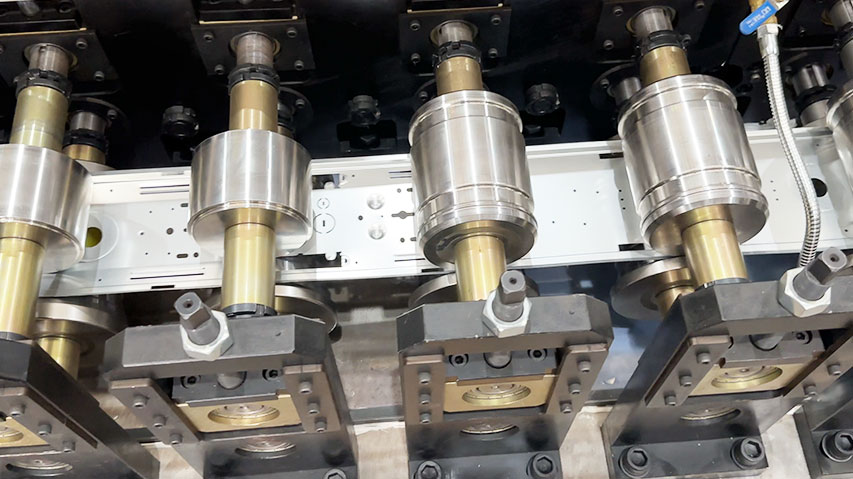

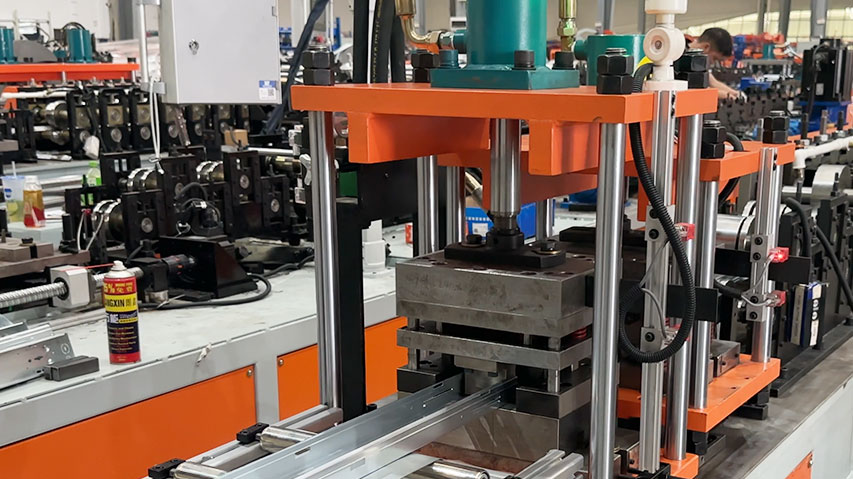

Independent Arch Frame Structure

Armdax uses independent Arch Frame Structure for roll forming of products, effectively suppressing torsional deformation caused by continuous operation. The stability of the worktable is increased by 40%, ensuring that product dimensional tolerances consistently remain within ±0.2mm, and it is compatible with continuous production of various material thicknesses (0.2-5.0mm).

Auto-Cut Technology for LED Aluminum Profiles

Fully synchronized with the roll forming line for continuous operation and optimal efficiency. Clean, ready-to-use LED aluminum channels with no deformation or marks. Minimize waste and boost productivity with automated, high-speed cutting. Ideal for LED profile manufacturers seeking speed, precision, and quality.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: How to get a quotation for an ARMDAX roll forming machine?

A:

To receive an accurate quotation, please provide profile drawings, material thickness, production speed requirements, and target market. ARMDAX will offer a professional proposal and competitive price for your roll forming machine project.

Q: Can ARMDAX roll forming machines be integrated with automatic systems?

A:

Yes. ARMDAX roll forming lines can be integrated with automatic punching, servo cutting, stacking systems, and PLC control systems, improving production efficiency and reducing labor costs.

Q: Can your roll forming machine form both steel and aluminum?

A:

Yes, most of our standard models can form both galvanized steel and aluminum coils. The produce materials with thicknesses ranging from 0.2mm to 5mm,and have the thickness adjustment . Please consult our engineers for your specific material requirements

Q: What is the maximum speed and output of your machines?

A:

Armdax roll forming machines have a line max speed up to 35 meters per minute. The actual output depends on the profile complexity and operator efficiency.