Appliance & Kitchenware Automated Production Line

Power your outdoor construction projects with our high-strength roll forming machines. Engineered for durability, they efficiently produce precise, long-lasting panels and components for solar, cladding, fencing, and structural systems.

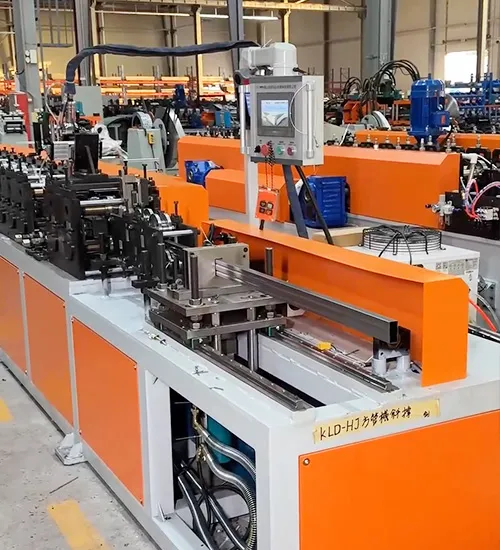

Robust Roll Forming Systems for Fan Housing Frames

We engineer durable production lines for high-demand commercial appliance components like electrical panels, frames, housings, etc. Our systems are built to handle stainless steel and produce strong, easy-to-clean profiles that meet the rigorous detection and durability standards of the many industries.

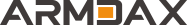

Metal Sheet Roll Forming Line Process

Show the Fan Housing Frame Cases

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for fan housing frames. Here is a showcase of customizations we have made for commercial appliance factories.

The Manufacturing Form of Innovation: ARMDAX.

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

Armdax Hydraulic Punching System

Armdax punch precise holes for clips and connectors directly in the forming process. Eliminate costly secondary operations. Hydraulic force delivers clean, burr-free holes in heavy-duty steel, ensuring perfect structural integrity. And Easily adapt punching patterns for different shelf models with quick tooling changes, which perfect for custom LED aluminum channels and applicable to porous production.

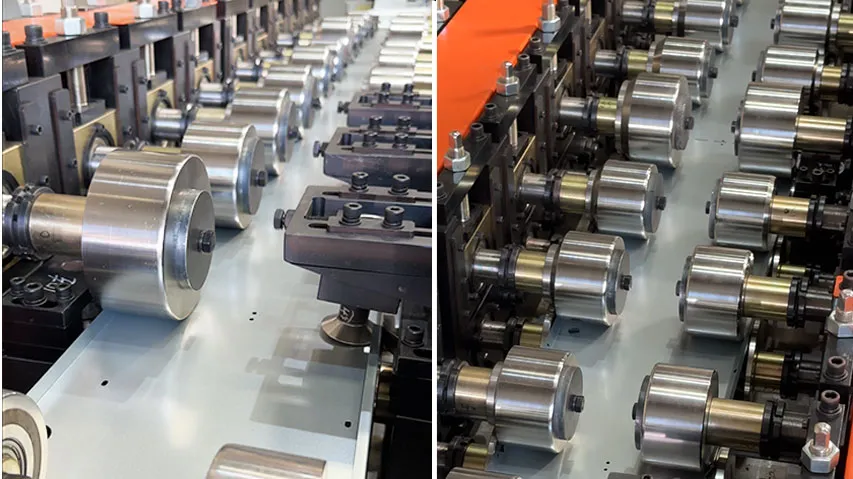

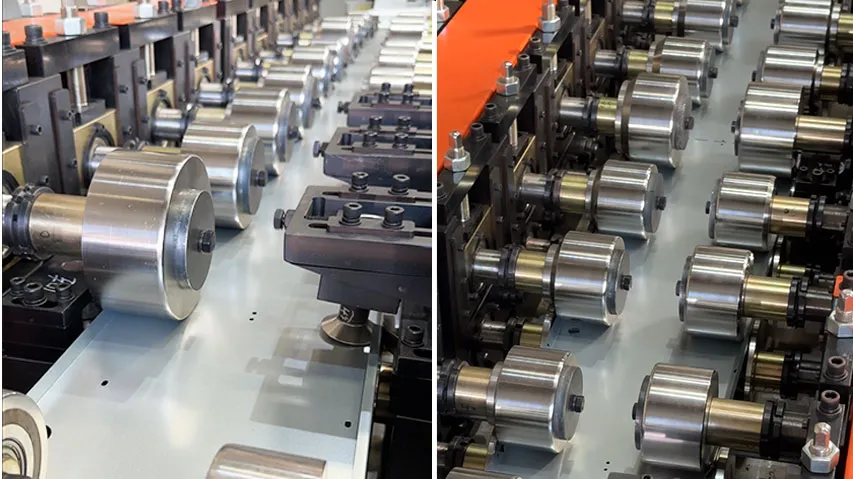

Precision Roll Forming System

Critical components are manufactured to the highest standards. Rollers are precision-machined on CNC lathes. Main shafts, are made from Cr12MoV alloy steel, tempered and precision-ground for maximum rigidity. The main frame side plates are machined from solid steel plates in a single setup on a CNC machining center to ensure perfect alignment. This robust construction guarantees the machine's longevity and reliability for years of demanding operation. According to the design drawings, implement the rolling process to achieve the preliminary product shape.

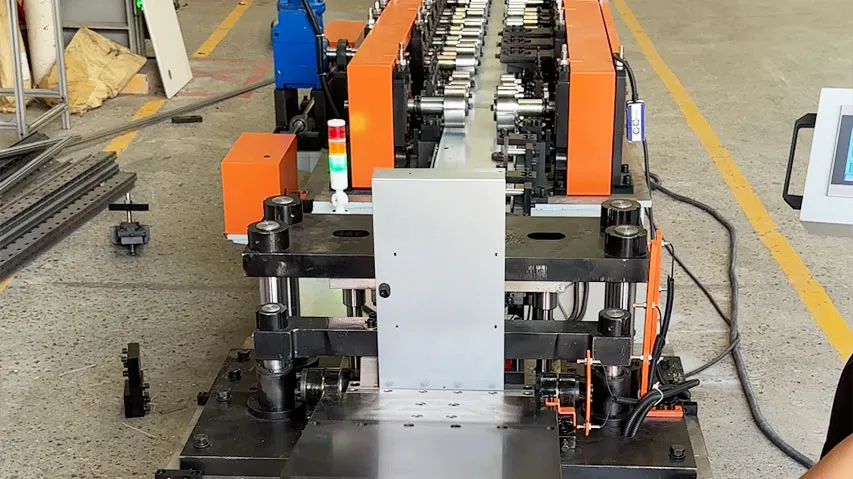

Auto Flanging For Fan Housing Frame Machine

Integrated directly into the production line, the automated flanging unit precisely bends the edges of the continuously moving frame panel, creating a strong, uniform vertical rim in a single pass.The flanging operation occurs immediately after the main profile is formed and before cutting, ensuring a continuous, uninterrupted workflow without secondary handling.The formed flange acts as a robust reinforcement beam, significantly increasing the frame's load-bearing capacity and resistance to bending or deformation.

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material: | Material Thickness: |

| Product Width Range: | Margin of error: |

| Drive System: | Form speed: |

| Control System: | Roller material: |

Download Full Technical Proposal

Download Full Technical ProposalYou Might Also Like

Ready to Optimize Your Production?

FAQS

Q: Can I visit your factory?

A:

Absolutely, we warmly welcome you to visit our factory. Please let us know your preferred dates, and we will make the necessary arrangements to accommodate your visit to ARMDAX , and show our modern and intelligent cold roll forming machine factory. Contact us Now !

Q: Do you provide installation and training?

A:

Yes, we provide detailed installation manuals and video guides. We also offer optional overseas engineer dispatch for on-site installation and training, with all costs (travel, accommodation) quoted separately.

Q: What is the warranty policy of ARMDAX machines ?

A:

We provide warranty service within 1 year, for wearing parts, free replacement within half a year. Detailed warranty terms are provided in our contract.