Recommend Top 5 Roll Forming Machine Manufacturers in China

Nov 05, 2025

Read:358

Source: Armdax

China has established itself as a global hub for industrial machinery, offering a compelling combination of advanced technology, robust manufacturing, and competitive pricing. For businesses worldwide, sourcing a roll forming machine from China can be a strategic move to enhance productivity and gain a competitive edge.

However, with countless options available, identifying the right partner is crucial. This article cuts through the noise to bring you five of the most reputable roll forming machine manufacturers in China, helping you make an informed decision.

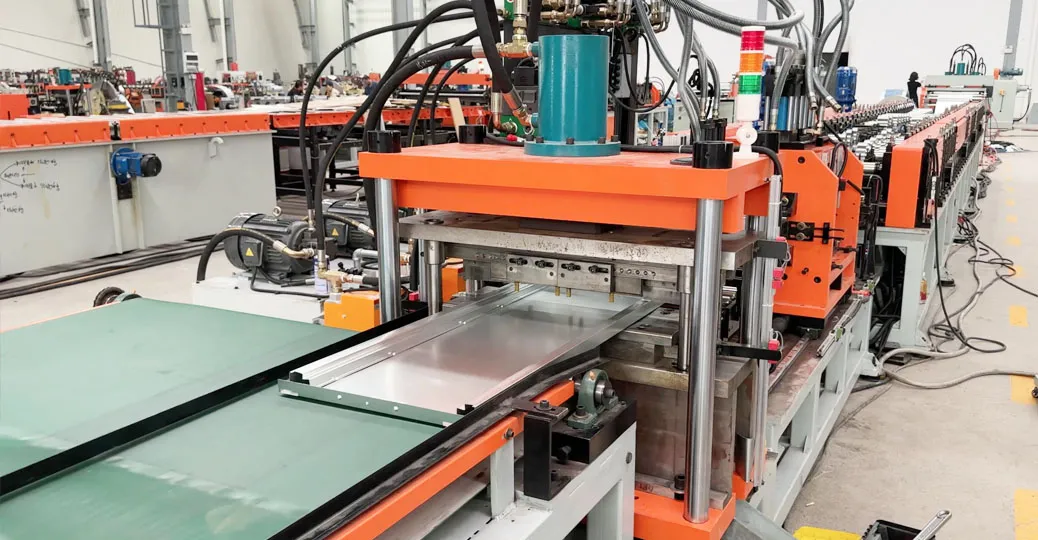

1. ARMDAX: The Specialist in Customized & Automated Solutions

Overview: ARMDAX has carved a niche for itself by focusing on high-precision, fully automated roll forming lines and bending center. They are known for their strong R&D capabilities and flexibility in engineering solutions for complex profiles.

Key Strengths:

Deep Customization: Excels at building machines for unique profiles, from heavy-duty structural beams to delicate trim.

Advanced Automation: Integrates punching, notching, and embossing directly into the production line for maximum efficiency.

Technical Support: Provides comprehensive support, from initial design consultation to installation and training.

Ideal For: Manufacturers looking for a true technical partner to develop custom production lines for specific applications.

Website: www.armdax.com

2. BOSJ: The Industry Veteran with a Wide Product Range

Overview: With decades of experience, BOSJ is a well-established name known for its extensive catalog of standard and custom roll forming machines. They serve a broad spectrum of industries, from construction to automotive.

Key Strengths:

Proven Track Record: Long history and a vast installed base globally attest to their reliability.

Comprehensive Range: Offers everything from simple C/Z purlin machines to complex sandwich panel lines.

Global Distribution: Strong after-sales network and readily available spare parts.

Ideal For: Businesses seeking a reliable, all-round manufacturer with a proven history for a wide variety of standard applications.

3. HARSLE: The Leader in Robustness and Heavy-Duty Applications

Overview: HARSLE has built a reputation for manufacturing incredibly durable and powerful machines designed for high-volume, heavy-duty production. Their machines are synonymous with longevity and minimal downtime.

Key Strengths:

Unmatched Durability: Frames and components are built to withstand 24/7 operation under demanding conditions.

Heavy-Gauge Expertise: Specializes in machines that can handle thicker and higher-strength materials.

Focus on Output: Engineering priorities are centered on maximizing throughput and uptime.

Ideal For: High-volume production environments where machine uptime and durability are the top priorities.

4. BHD: The Innovator in Smart Manufacturing

Overview: BHD positions itself at the forefront of Industry 4.0. They integrate IoT (Internet of Things) capabilities, data monitoring, and advanced control systems into their roll forming lines.

Key Strengths:

Smart Factories: Machines equipped for predictive maintenance and real-time performance monitoring.

Precision Engineering: Focuses on ultra-high precision for industries like aerospace and specialized electronics.

User-Friendly Tech: Intuitive PLC controls and simulation software for easier operation and programming.

Ideal For: Forward-thinking companies aiming to build a smart factory and leverage data for operational efficiency.

5. CANGTIAN: The Champion of Value and Entry-Level Solutions

Overview: CANGTIAN offers a strong balance between cost and performance, making them an excellent entry point for small to medium-sized enterprises or those with budget constraints.

Key Strengths:

Competitive Pricing: Provides significant cost advantages without a complete sacrifice of quality.

Solid Performance: Machines are reliable and capable for standard applications like purlins and studs.

Responsive Service: Known for being agile and responsive to customer inquiries and needs.

Ideal For: Start-ups, SMEs, and businesses looking for the best value proposition to begin their automation journey.

Key Factors to Consider When Choosing the righ roll forming machine manufacturer in China

Before making a final decision, it's crucial to evaluate manufacturers based on your specific needs:

Your Product Profile: How complex is your cross-section? Does it require in-line punching?

Required Output & Speed: What is your target production volume (meters per minute)?

After-Sales Service: What level of installation, training, and technical support is offered? How available are spare parts?

Factory Visit & References: Always request client references and, if possible, visit the factory to assess their manufacturing capabilities and quality control firsthand.

SO, The "best" manufacturer depends entirely on your unique production requirements, budget, and long-term goals. ARMDAX stands out for its custom engineering prowess, while BOSJ and HARSLE offer proven reliability for heavy-duty applications. BHD leads in smart technology, and CANGTIAN provides exceptional value.

Table of Contents