Armdax Precision Profile Automation Line: Revolutionizing Metal Forming Production

Nov 03, 2025

Read:178

Source: Armdax

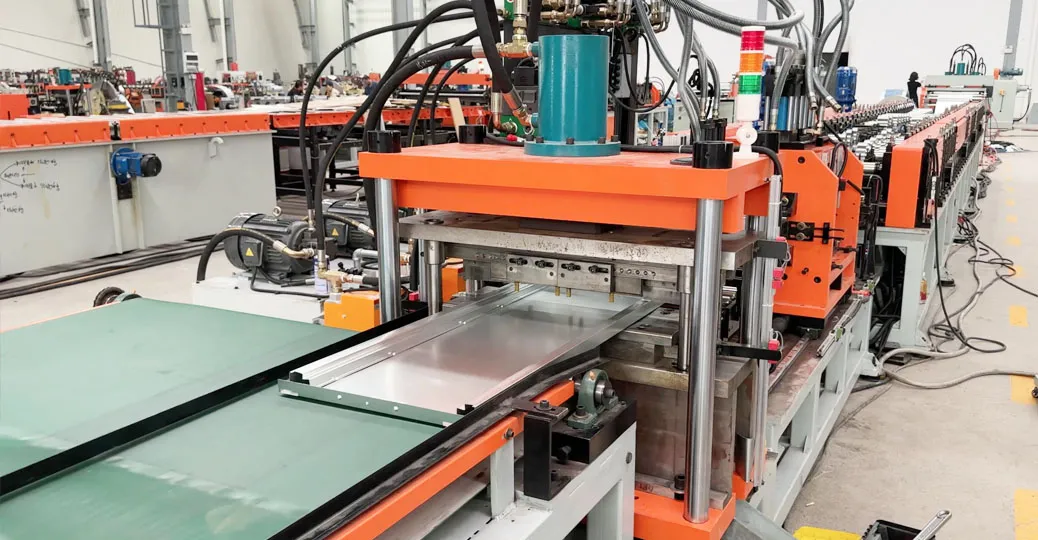

Modern manufacturing demands efficiency, accuracy, and versatility. Armdax profile automated production line meets these challenges head-on, integrating advanced technology to streamline the entire manufacturing process from input to output. This system is engineered for manufacturers seeking to enhance productivity while maintaining uncompromised quality in C-sections, J-profiles, columns, and other structural components.

Key Features of the Automated Production Line

1.Seamless Parameter-Based Operation

Simply input product specifications—length, hole spacing, quantity—and watch the system execute punching, forming, and cutting in one continuous, automated sequence. This eliminates manual adjustments and significantly reduces processing time.

2.Advanced Servo Flying Cut Technology

The heart of the line lies in its servo-driven flying cut system. Unlike traditional methods, it performs precise cuts without stopping the production flow. This ensures:

Zero Downtime: Uninterrupted operation for higher throughput.

Exceptional Accuracy: Tolerances within ±0.5mm for consistent dimensions.

Burr-Free Finishes: Clean edges ready for assembly or further processing.

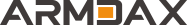

3. Broad Material and Profile Compatibility

From C-purlins and J-trims to structural columns, the line adapts effortlessly to diverse profile designs. Its flexibility makes it ideal for:

Construction frameworks

Shelving systems

Architectural trim

Industrial supports

Benefits for Your Business

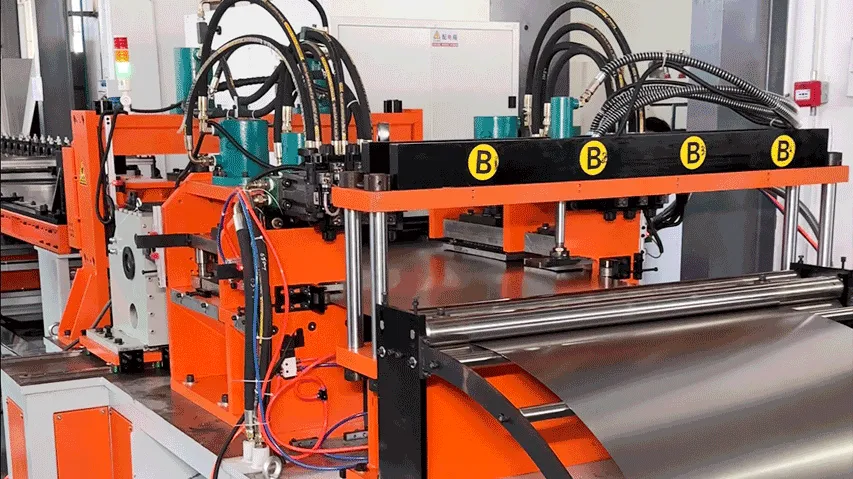

Stability: Robust construction ensures reliable 24/7 performance.

Speed: High linear production rates (e.g., 15-25m/min) slash lead times.

Precision: Consistent quality across large batches reduces rework and waste.

Conclusion

Embrace the future of metal profile manufacturing with a solution that combines intelligence, speed, and precision. Armdax profile automated line isn’t just machinery—it’s your partner in achieving scalable, cost-effective production.

Explore how our automation can transform your output. Request a customized solution today!

Table of Contents