Looking for A Roll Forming Line for Shelving? Here Is A Recommendation

Nov 18, 2025

Read:202

Source: Armdax

In the competitive storage and shelving industry, efficiency, consistency, and cost-effectiveness are not just goals—they are the bedrock of profitability. If you are looking to upgrade your production, expand your capacity, or start a new manufacturing line, investing in a high-quality roll forming line for shelving is the most critical decision you will make.

But with numerous options available, how do you choose the right partner? This article provides a comprehensive guide and a strong recommendation to help you navigate this important investment.

Key Considerations When Choosing a Shelving Roll Forming Line

Not all roll forming lines are created equal. Your choice should be based on the specific demands of the shelving market.

1.Versatility and Customization:

The Challenge: You need to produce a variety of profiles—C-purlins for frames, box beams for uprights, and specific channel designs for shelf panels.

The Solution: The line must have quick-change tooling and a flexible design to switch between different profiles with minimal downtime, allowing you to respond to diverse customer needs.

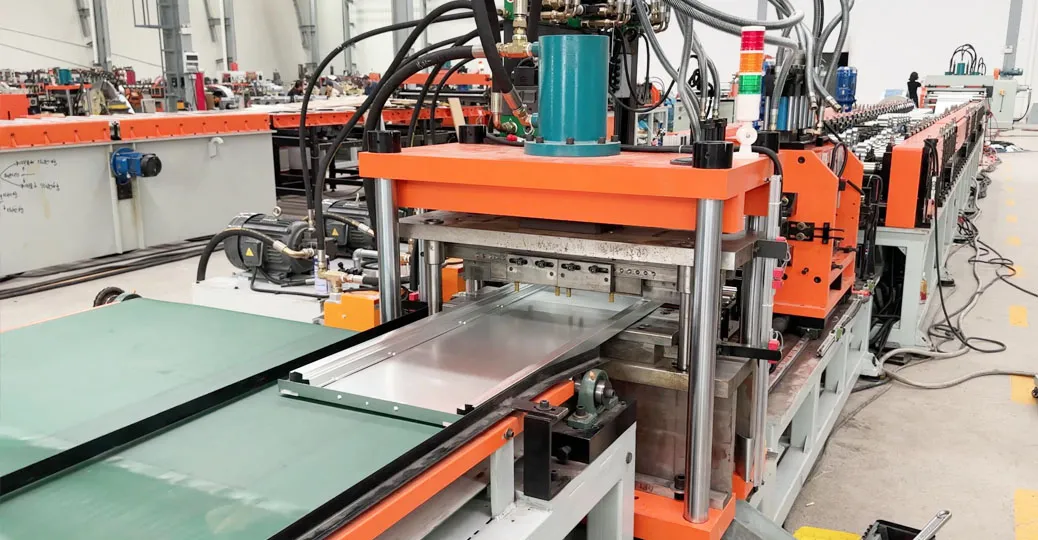

2. Integrated Punching and Notching:

The Challenge: Shelving components require precise holes for bolts, connectors, and adjustable shelf pins. Secondary operations are slow and costly.

The Solution: A top-tier line integrates servo-driven punching stations that accurately punch holes, notches, and embossments in-line, transforming coiled steel into a finished, ready-to-assemble part in one continuous process.

3.Production Speed and Stability:

The Challenge: Meeting large order volumes and tight deadlines requires high throughput without sacrificing quality.

The Solution: Look for lines with robust frames, high-precision rollers, and advanced control systems that can maintain speeds of 20-30 meters per minute while ensuring every component is identical.

4.Durability and Low Maintenance:

The Challenge: Production lines are long-term investments. Frequent breakdowns lead to expensive downtime.

The Solution: The machinery should be built with hardened alloy steel rollers and heavy-duty structural components to withstand 24/7 operation.

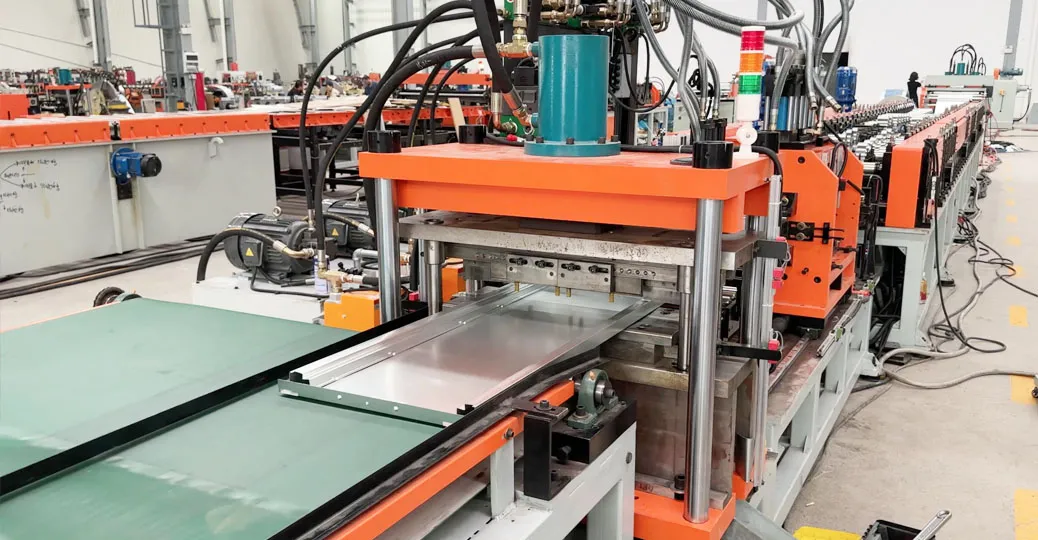

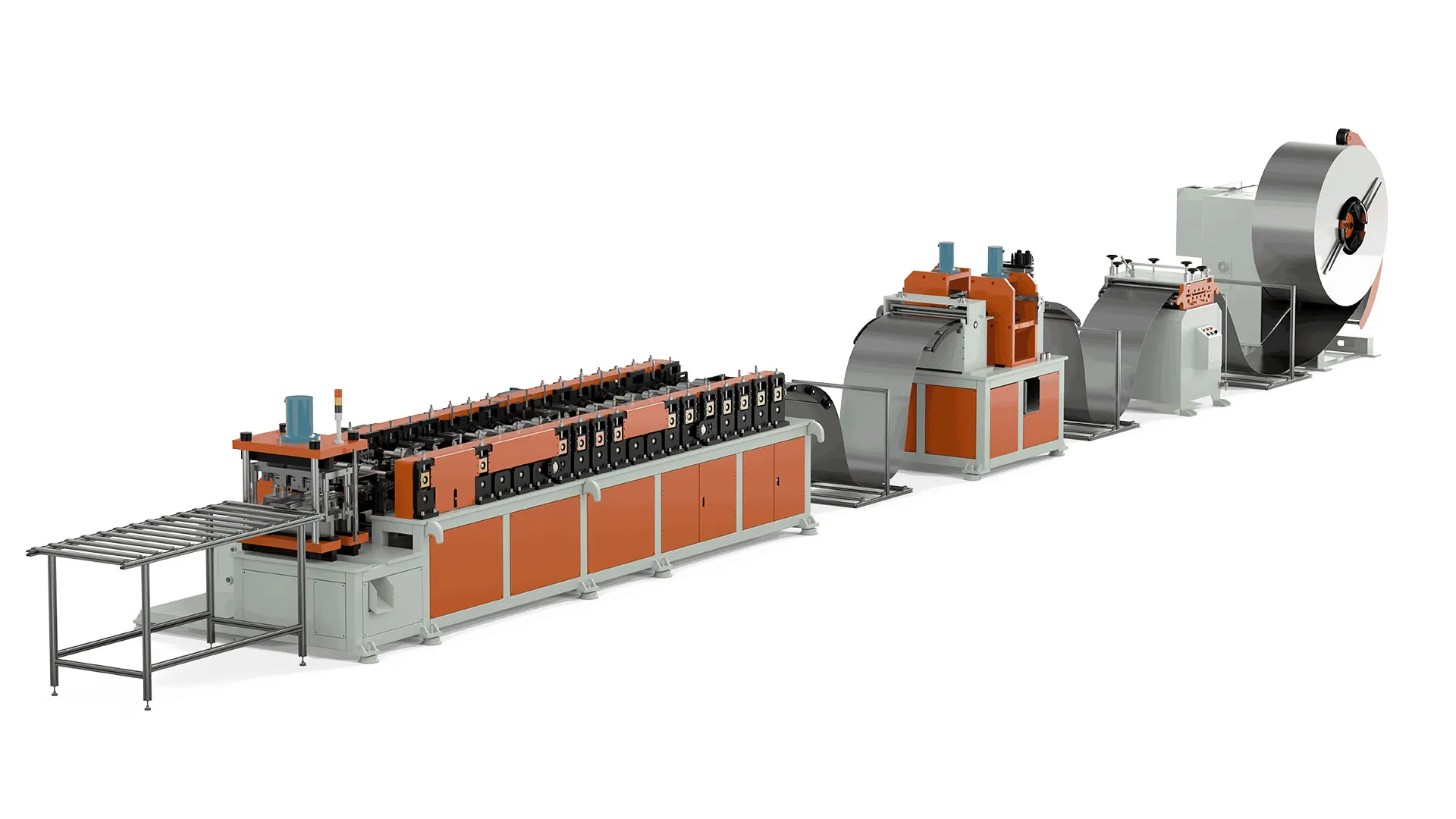

Why ARMDAX is the Recommended Choice for Your Shelving Production

After evaluating the key criteria, one manufacturer consistently meets and exceeds these requirements: ARMDAX. Here’s why we confidently recommend them for your shelving roll forming lines.

Two Decades of Specialized Expertise

With over 20 years of focused experience in roll forming technology, ARMDAX possesses deep, specialized knowledge in designing lines for the storage industry. They are not a generic machinery supplier; they are shelf manufacturing specialists. This expertise translates into machines that are perfectly tailored to the unique challenges of producing strong, precise, and cost-effective shelving components.

Uncompromising Quality and Reliability

ARMDAX builds its lines to last. From the selection of raw materials to the final assembly, quality control is paramount. Their reputation for reliability means your production schedule is secure, and your total cost of ownership is lowered over the machine's lifespan.

Advanced, Smart Technology

ARMDAX integrates modern automation and smart features into their lines:

*User-Friendly PLC Control: Simplifies operation and changeovers.

*Precision Flying Cut Systems: Ensure clean, burr-free cuts to exact lengths without stopping the line.

*IoT Readiness: Many lines offer data monitoring capabilities for predictive maintenance and production optimization.

A Customized Solution for Every Client

ARMDAX understands that every shelving manufacturer has unique needs. They don't just sell standard machines; they engineer customized solutions. By providing your component drawings and production goals, their expert team will design a roll forming line that perfectly fits your operation, maximizing your output and profitability.

The Advantage Of ARMDAX roll forming line for shelving

By choosing an ARMDAX roll forming line for shelving, you can expect:

Drastically Reduced Labor Costs: Automation reduces dependency on manual labor.

Increased Production Output: High-speed lines significantly boost your capacity.

Minimized Material Waste: Precision engineering ensures optimal material usage.

Enhanced Product Quality: Every beam, upright, and panel is consistently perfect, leading to stronger and easier-to-assemble final products.

Faster Return on Investment (ROI): The combination of higher efficiency and lower operating costs ensures a quick payback period.

When your business success depends on the efficiency of your shelving production, the choice of equipment partner is paramount. While many manufacturers exist, ARMDAX stands out for its proven track record, commitment to quality, and ability to deliver smart, customized roll forming solutions.

Don't just buy a machine—invest in a partnership that will power your growth for years to come.

Ready to Transform Your Shelving Production?

Contact ARMDAX today for a free, no-obligation consultation. Provide them with your profile ideas, and their engineering team will recommend the perfect roll forming line to help you dominate your market.

Table of Contents