How to Choose a Cable Tray Roll Forming Machine?

Jan 08, 2026

Read:111

Source: Armdax

In the electrical and construction industries, cable tray systems are essential for organizing and protecting cables. A cable tray roll forming machine is at the heart of manufacturing these systems, transforming metal coils into precise, durable cable trays. Choosing the right machine is critical for product quality, operational efficiency, and long-term profitability. This comprehensive guide will walk you through the key factors to consider when selecting the perfect cable tray roll forming machine for your needs.

1. Understand Your cable tray Production Requirements

Before diving into specifications, clearly define your needs.

Output Capacity: Determine your required production speed (e.g., meters per minute) and daily/weekly volume. High-volume manufacturers need high-speed, automated lines, while smaller shops may prioritize flexibility.

Cable Tray Type & Size: What types will you produce? (e.g., ladder-type, solid-bottom, wire mesh, channel). Define the range of widths, depths, and side heights (flange heights) you need.

Material Specifications: Identify the type (galvanized steel, stainless steel, aluminum), thickness (gauge), and coil width you will primarily use.

Future-Proofing: Consider potential business growth. Can the machine handle a broader range of profiles or increased capacity in the future?

2. Key Machine Components and Features to Evaluate

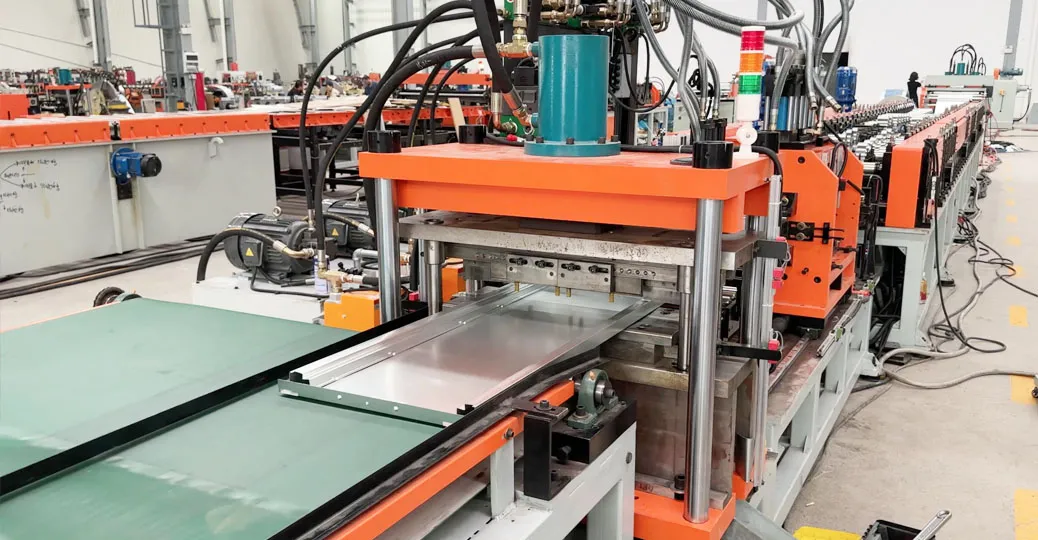

A. The Roll Forming Station

Number of Stations: More forming stations allow for more complex profiles and smoother, higher-precision bends, especially for thicker materials.

Shaft & Gearbox Quality: Look for robust, hardened steel shafts and high-torque gearboxes. This ensures stability, reduces vibration, and extends tooling life.

Frame Structure: A heavy-duty, reinforced frame minimizes deflection under load, ensuring consistent profile accuracy.

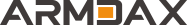

B. Tooling (Rolls & Dies)

Material & Craftsmanship: Tooling should be made from high-grade alloy steel (e.g., Cr12, 42CrMo) and heat-treated for durability. Precision grinding ensures a smooth finish and long service life.

Design & Compatibility: Ensure the tooling is designed for your specific cable tray profile and material thickness. Quick-change systems can drastically reduce downtime when switching profiles.

Supplier Expertise: Choose a machine supplier with proven experience in designing cable tray-specific tooling.

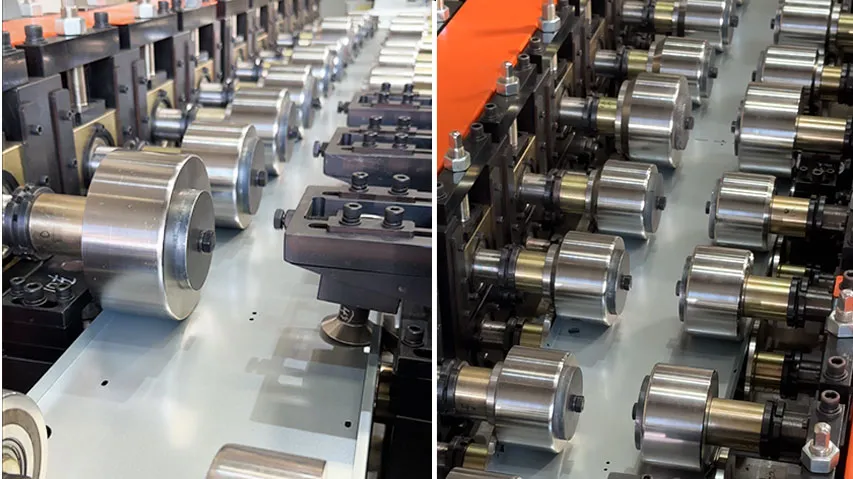

C. Decoiler & Straightener

Capacity: The decoiler must handle your maximum coil weight and width.

Automatic Features: An automatic hydraulic decoiler with a coil car and edge guiding system improves safety and efficiency for heavy coils.

Precision Straightening: A 5-7 roll straightening unit is crucial for removing coil set and ensuring flat, uniform material feeding, which is vital for final product quality.

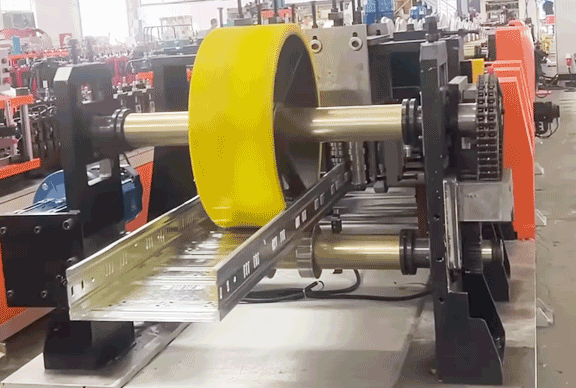

D. Cutting System

Type of Cutter: This is a critical choice.

Flying Cut-Off: Cuts on-the-fly without stopping the line, essential for high-speed production (>25m/min).

Hydraulic Punch & Cut: Often used for making pre-punched ladder-type trays. It can combine punching and cutting in one unit.

Synchronized Servo Cut-Off: Offers the highest precision and cleanest cut with programmable lengths. Ideal for complex or high-value products.

Accuracy & Burr: Investigate the cutting tolerance and the level of burr produced. A good cutter leaves a clean, safe edge.

E. Control System & Automation

PLC & HMI: A user-friendly Programmable Logic Controller (PLC) and Human-Machine Interface (HMI) touchscreen allow for easy setup, length programming, fault diagnosis, and speed adjustment.

Servo Drives: Servo motors for feeding and cutting provide superior accuracy and flexibility compared to traditional hydraulic or pneumatic systems.

Automation Integration: Consider options like automatic stacking, packing, or transfer systems to reduce labor and increase line efficiency.

3. Assess the Supplier Reliability and Support

Manufacturer Reputation: Research the company's history, client testimonials, and industry presence. A reputable supplier is a long-term partner.

Technical Support & Training: Ensure they offer comprehensive installation, commissioning, and operator training.

After-Sales Service: Clarify warranty terms, spare parts availability, and the responsiveness of their service team. Local support can be a significant advantage.

Factory Visit & Testing: If possible, visit the supplier's factory to see the machine's build quality and request a production test using your own material specs.

4. Balance Budget with Total Cost of Ownership (TCO)

The cheapest machine often has the highest long-term cost. Look beyond the initial price.

Energy Efficiency: Machines with servo systems often consume less power.

Maintenance Costs: Robust construction and standard-quality components reduce breakdowns and part replacement costs.

Product Yield: A precise, stable machine minimizes material waste from rejects or out-of-spec production.

Durability: An investment in a well-built machine pays off over a decade or more of reliable service.

Conclusion: Your Decision Checklist

To make an informed decision, answer these questions:

Does the machine meet my current profile, size, and output requirements?

Is it robust and precise enough for my material (especially thickness)?

Does the cutting system match my desired speed and finish quality?

Is the control system modern and easy for my team to operate?

Can the supplier provide strong after-sales support and quality tooling?

Does the Total Cost of Ownership align with my business model and budget?

Choosing the right cable tray roll forming machine is a strategic investment. By thoroughly analyzing your production needs, meticulously evaluating machine features, and partnering with a reliable supplier, you can secure equipment that enhances your product quality, boosts your competitiveness, and ensures a strong return on investment for years to come.

Table of Contents