How To Choose Steel Wall Panel Roll Forming Machines Can Further Enhance Efficiency?

Nov 25, 2025

Read:158

Source: Armdax

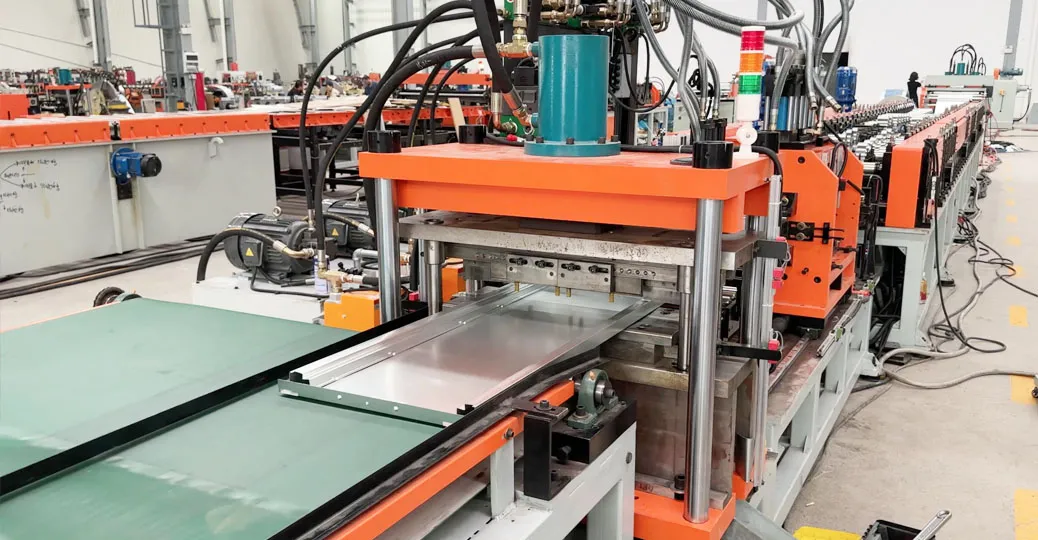

Revolutionizing Building Envelopes with Automated Steel Panel Production

In modern construction, efficiency and precision in structural cladding are non-negotiable. Steel wall panel roll forming machines have emerged as the cornerstone technology for manufacturers and construction firms seeking to produce high-quality, consistent building envelopes at competitive costs. These automated systems transform raw steel coils into perfectly formed wall panels in a continuous, streamlined operation.

How Steel Wall Panel Roll Forming Machines Work

The production process exemplifies manufacturing efficiency:

Coil Loading & Feeding

Automatic decoilers handle 3-5 ton steel coils

Precision servo feeders maintain consistent material flow

Leveling & Guide Alignment

7-roller leveling systems eliminate coil curvature

Edge guiding ensures perfect material tracking

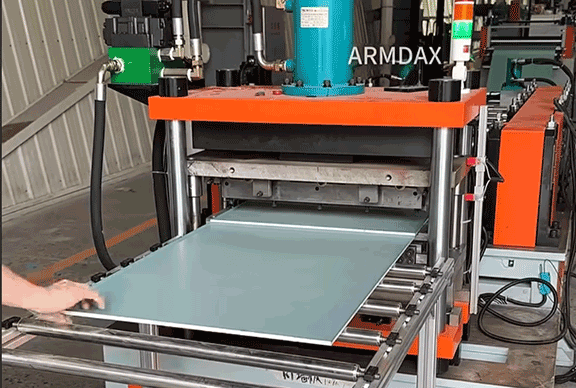

Progressive Profile Forming

18-24 forming stations gradually shape the panel

Interlocking seams, drainage channels, and architectural features are formed in-sequence

Cut-to-Length & Output

Flying cut systems deliver accurate lengths (±1mm)

Automatic stacking organizes finished panels

Key Advantages for Construction Projects

Superior Production Efficiency

Output speeds of 15-30 meters/minute

Reduced labor costs through automation

Minimal material waste versus traditional fabrication

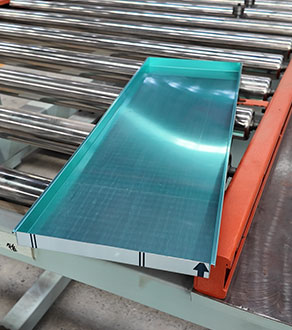

Unmatched Quality Consistency

Every panel identical in dimensions and profile

Consistent interlocking mechanisms for weathertight seals

Perfect for large-scale projects requiring standardized components

Design Flexibility

Quick changeovers between different panel profiles

Accommodates various steel types and coatings

Custom profiles for architectural specifications

Technical Specifications of Armdax Steel Wall Panel Roll Forming Machines

| Parameter | Specification Range |

| Material Thickness | 0.2mm - 5mm |

| Panel Width | Servo Adjustable |

| Line Speed | 10-25 meters/minute |

| Power Requirements | 20-40 kW |

| Control System | Mitsubishi PLC or other Optional |

Choosing the Right Roll Forming Machine

Consider Your Production Needs:

Volume Requirements: High-speed lines for large projects vs. flexible systems for custom work

Panel Types: Architectural cladding, industrial wall systems, or composite panels

Material Specifications: Galvanized steel, aluminum, or pre-painted coils

Why ARMDAX Delivers Excellence:

20+ years specializing in construction machinery

Custom engineering for specific project requirements

Comprehensive training and support services

CE-certified equipment with global service network

Industry Applications

Commercial Buildings: Office complexes, retail centers

Industrial Facilities: Warehouses, manufacturing plants

Agricultural Structures: Storage buildings, livestock facilities

Institutional Projects: Schools, hospitals, government buildings

Maximizing Your Investment

Long-term Value Considerations:

Energy-efficient servo motor systems

Quick-change tooling for reduced downtime

Remote monitoring capabilities

Local technical support availability

Success Metrics:

40-60% reduction in production costs versus manual fabrication

3-5x increase in output capacity

Consistent quality eliminating installation issues

Enhanced competitiveness through custom profile capabilities

Transform Your Wall Panel Production Today

ARMDAX roll forming machines represent more than equipment—they're strategic partners in building excellence. From standard profiles to custom architectural solutions, our technology ensures your projects meet the highest standards of quality, efficiency, and cost-effectiveness.

Contact us for a personalized consultation and discover how our steel wall panel solutions can elevate your construction capabilities.

Table of Contents