ARMDAX Roll Forming Solutions: Powering the Modern Steel Furniture Manufacturing

Nov 21, 2025

Read:191

Source: Armdax

Discover how ARMDAX roll forming machines boost efficiency & cut costs for steel furniture makers. From bed frames to cabinets, get custom, automated production solutions.

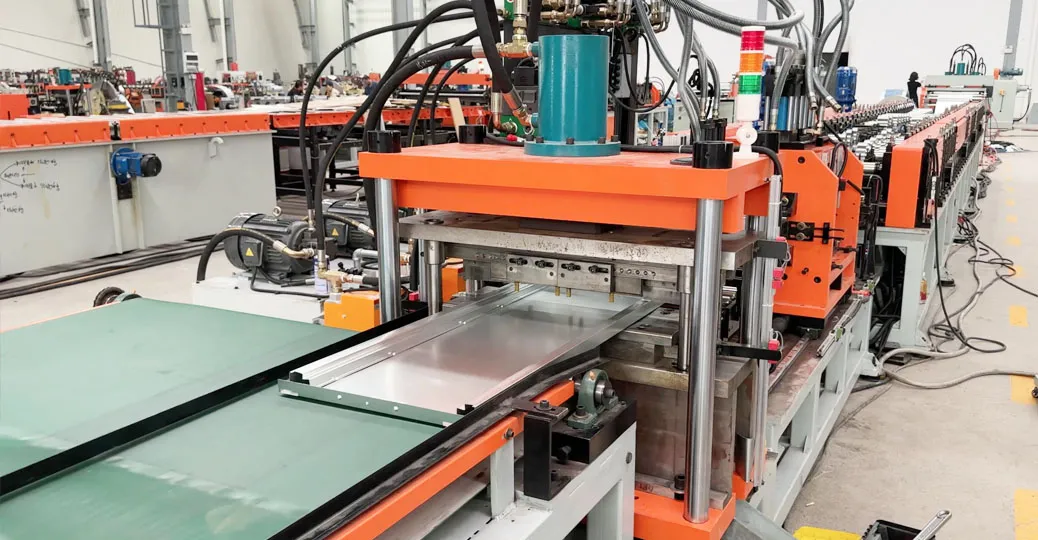

The steel furniture industry demands more than just durability; it requires speed, design flexibility, and cost-efficiency. In this competitive landscape, manufacturers are turning to automation to stay ahead. ARMDAX stands as a leading partner, providing high-precision roll forming solutions that transform raw steel into the strong, consistent skeletons of modern furniture—from sleek office cabinets to robust bed frames and industrial shelving.

This article explores how ARMDAX technology is revolutionizing steel furniture manufacturing.

The ARMDAX Advantage: Engineered for Furniture Excellence

ARMDAX doesn't just sell machines; we provide integrated production systems. Our solutions are tailored to the unique needs of the furniture industry, offering distinct advantages over traditional manufacturing methods like press braking or manual welding.

1. Unmatched Production Efficiency & Speed

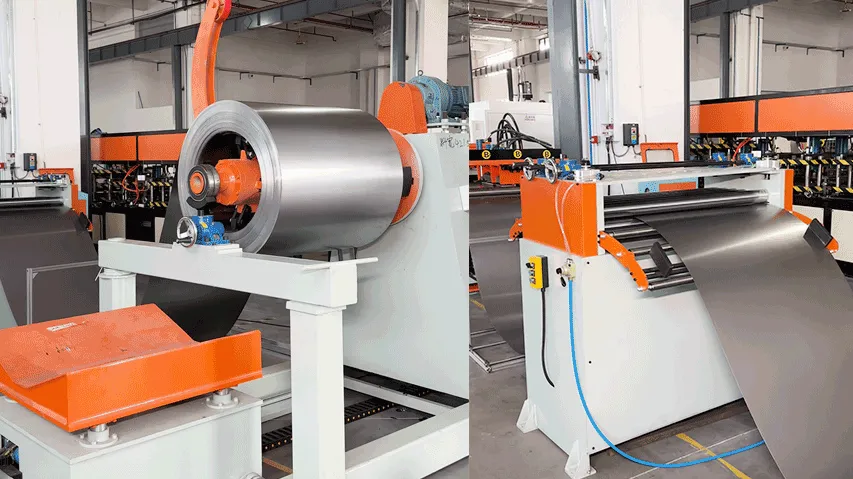

Continuous Operation: ARMDAX lines run 24/7, transforming steel coil into finished profiles at speeds of 20-30 meters per minute. This eliminates the bottlenecks of manual bending, slashing production times for high-volume orders.

Reduced Labor Costs: A single, automated roll forming line replaces multiple manual stations. One operator can manage the entire process, from decoiling to cutting, freeing your skilled labor for final assembly and quality control.

2. Superior Product Consistency & Quality

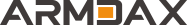

Perfect Replication: Every leg, frame, and support beam that comes off an ARMDAX line is identical. This precision ensures flawless assembly, reduces rejects, and guarantees your final product is perfectly square and structurally sound.

Flawless Finishes: Our precision rollers and guiding systems prevent scratches, marks, and oil canning on the material surface. This results in a pristine finish that is ready for powder coating, saving you time and money on post-processing.

3. Unparalleled Design Flexibility & Customization

Quick-Change Tooling: Switch between producing a bed frame channel, a furniture leg, and a cabinet reinforcement profile in minutes. This agility allows you to respond to market trends and fulfill custom orders without costly downtime.

In-Line Processing: Integrate punching, notching, and embossing directly into the production line. Create profiles with pre-punched holes for screws, connectors, or adjustable shelves, delivering a ready-to-assemble product.

4. Significant Material & Cost Savings

Minimized Waste: Precision forming and programmed cutting optimize material usage, leading to near-zero scrap. You pay for the steel you use, not the steel you throw away.

Optimized ROI: The combination of higher throughput, lower labor costs, and reduced waste ensures a rapid return on investment, typically within 12-24 months.

ARMDAX Solutions for Key Steel Furniture Products

Our machines are versatile enough to form the core components of virtually any steel furniture item:

Bed Frames: Produce strong, interlocking side rails and center supports with integrated connection points.

Office & Storage Cabinets: Form precise cabinet frames, doors, and shelving brackets with consistent dimensions for easy assembly.

Chairs & Tables: Create sturdy legs, frames, and reinforcement profiles for commercial and residential furniture.

Lockers & Shelving Units: Manufacture uprights, beams, and decking profiles with high load-bearing capacity.

Display Racks & Retail Furniture: Execute complex, aesthetically pleasing profiles for modern store fixtures.

Why ARMDAX is the Trusted Partner for Furniture Manufacturers

20+ Years of Specialization: Our deep expertise in roll forming is applied directly to the challenges of the furniture industry.

End-to-End Support: We partner with you from initial design consultation and CAD simulation to installation, training, and lifelong technical support.

In an industry where margins are tight and competition is fierce, the right machinery is not an expense—it's a strategic advantage. ARMDAX roll forming solutions provide the speed, precision, and flexibility that modern steel furniture manufacturers need to thrive.

Stop bending metal the old way. Start forming the future of furniture with ARMDAX.

Ready to Transform Your Furniture Production?

Contact ARMDAX today for a free, no-obligation consultation. Our engineering experts will analyze your needs and provide a customized solution to help you build better furniture, faster and more profitably.

Table of Contents