How do you think Armdax roll forming machcine manufacturer?

Aug 30, 2025

Read:415

Source: Armdax

You're searching for a reliable roll forming machine manufacturer, and you've likely come across ARMDAX. The critical question remains: Is ARMDAX the right partner for your factory's future?

Online specs and sales pitches only tell part of the story. The true measure of Armdax roll forming machine manufacturer lies in the experiences of its clients. After analyzing feedback from dozens of global manufacturers, we've compiled a clear-eyed look at what it's really like to partner with ARMDAX.

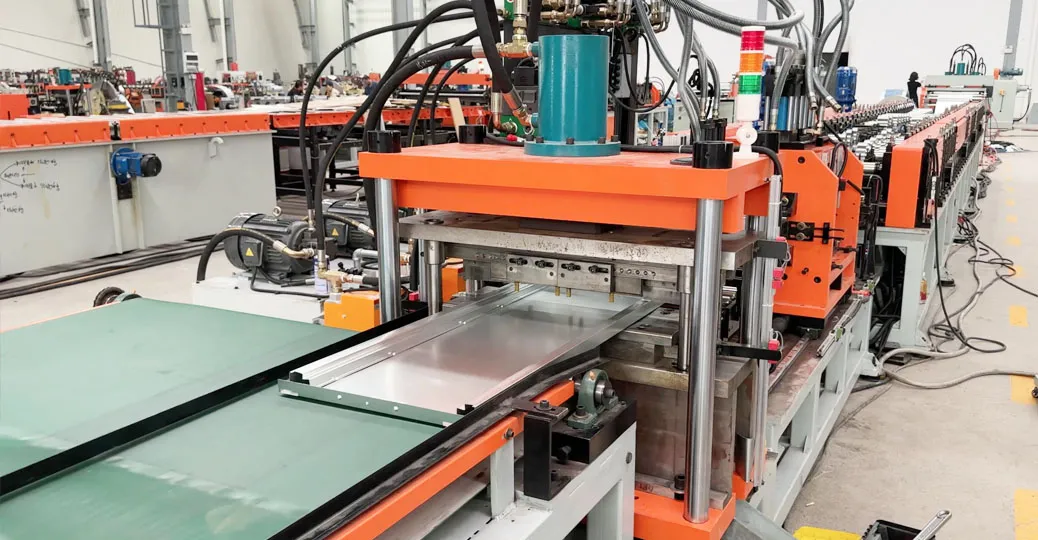

1. The Verdict on Build Quality: "Built Like a Tank"

This is the most consistent praise point across client reviews.

What Clients Say: "We've been running our ARMDAX line 24/7 for over two years with minimal downtime. The frame is incredibly rigid, and the hardened steel rollers show almost no wear."

Our Analysis: ARMDAX doesn't cut corners on materials. Their use of high-grade steel for the frame and precision-machined, hardened alloy rollers translates directly to long-term reliability and consistent product quality. For factories where uptime is profit, this is the number one reason they are chosen.

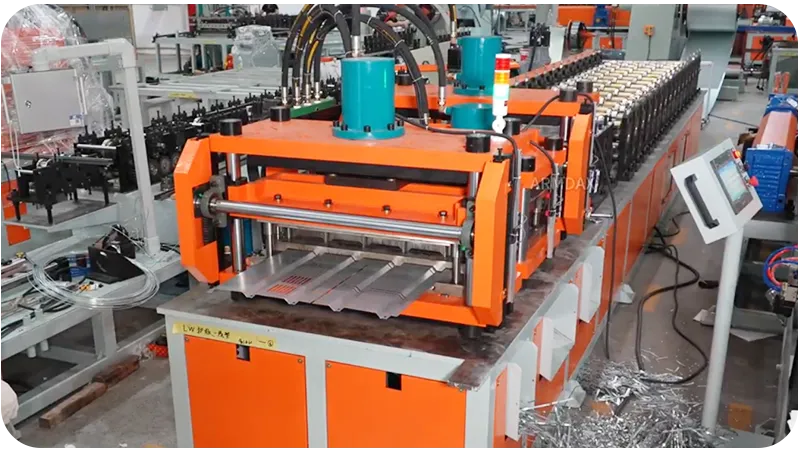

2. They Unique Challenge of Armdax roll forming machine manufacturer

Beyond standard machines, ARMDAX's core strength lies in solving complex problems.

What Clients Say: "We needed a custom profile for a new solar panel mounting system. Other suppliers hesitated, but the ARMDAX engineering team worked with us from the CAD stage to deliver a perfect solution."

Our Analysis: ARMDAX positions itself as a solutions provider, not just a machine seller. Their engineering team's ability to collaborate on custom roller design and machine configuration makes them a go-to for non-standard applications.

3. The Price-to-Performance Ratio: "Unexpectedly Affordable Quality"

How does ARMDAX balance cost and quality?

What Clients Say: "We compared machines from Germany and Turkey. The ARMDAX machine offered about 90% of the performance at 60% of the price. The ROI was a no-brainer."

Our Analysis: As a direct manufacturer based in China, ARMDAX provides a significant cost advantage without the dramatic sacrifice in quality often associated with low-cost options. They represent a sweet spot for SMEs and growing manufacturers seeking high value.

4. After-Sales Support: "The Support Team is Responsive and Knowledgeable"

This is often the biggest concern when buying machinery overseas. How does ARMDAX measure up?

What Clients Say: "During installation, we had a question about the PLC settings. Their engineer jumped on a video call and walked us through it in real-time. Spare parts were shipped via DHL within days."

Our Analysis: While no company is perfect, the consensus is that ARMDAX's support is responsive and effective. They leverage modern communication tools (WhatsApp, video call) to provide remote assistance. The availability of a comprehensive lifelong spare parts supply is a critical peace-of-mind factor.

Considerations and Who It's Best For

No manufacturer is perfect for everyone. Based on client experiences, ARMDAX is the ideal partner if:

You are a small to medium-sized factory looking to automate and scale.

You need a customized solution but have a budget that European manufacturers can't meet.

You value robust build quality and long-term machine longevity.

You have a technically competent team that can collaborate effectively with remote engineers.

They might not be the best fit if your primary requirement is localized, on-the-ground service engineers in Europe or North America, which typically comes with a much higher price tag from Western brands.

Frequently Asked Questions (FAQs)

Q: Does ARMDAX provide installation and training?

A: Yes, they provide detailed manuals, video guides, and real-time remote support. On-site installation by their engineers is typically available as an optional, paid service.

Q: What is the typical production lead time?

A: For standard machines, expect 30-45 days. Fully custom lines may take 60-90 days. They provide a clear timeline upon order confirmation.

Q: How is the machine packaged for shipping?

A: Export-standard, heavy-duty wooden crates are used to ensure the machine arrives safely, even with long-distance ocean freight.

Final Conclusion

So, how do we think about ARMDAX Roll Forming Machine Manufacturer?

The overwhelming evidence from the market suggests that ARMDAX is a highly competent, reliable, and value-driven partner. They have successfully carved out a niche by delivering German-level engineering sensibility at a cost that is accessible to the global majority of manufacturers.

They have built their reputation not on flashy marketing, but on solid machines that perform day in and day out on the factory floors of their clients.

Ready to See for Yourself?

Don't just take our word for it. Contact ARMDAX today to:

Request customer reference videos from your industry.

Get a free, no-obligation quote for your project.

Discuss your specific profile needs directly with their engineering team.

Table of Contents