Automatic Bending Machine Vs Electric Servo Press Brake, Comparison for Smart Manufacturing

Dec 09, 2025

Read:278

Source: Arndax

In the competitive world of sheet metal fabrication, choosing the right bending technology is crucial for efficiency, precision, and profitability. Two terms often dominate the conversation: the Automatic Bending Machine and the Electric Servo Press Brake. While both aim to automate the bending process, they represent different philosophies and technological levels. Understanding their differences is key to making a strategic investment that will power your factory's future.

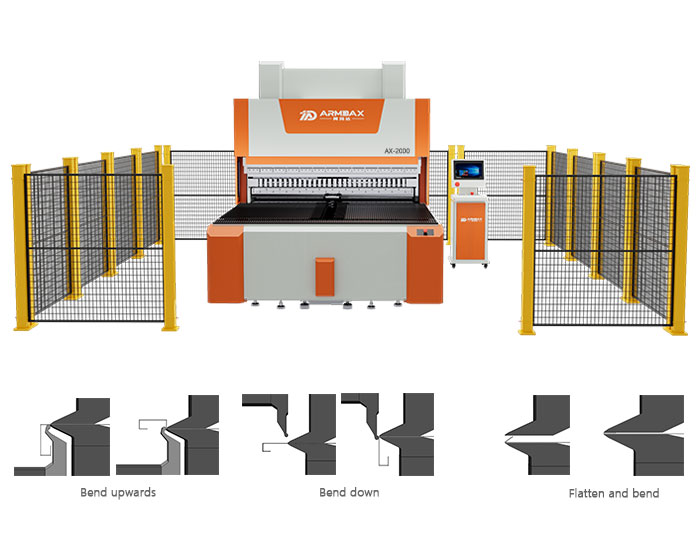

This guide breaks down these two technologies and explains why ARMDAX's advanced solutions are attracting global attention.

An Automatic Bending Machine makes a manual process faster. An ARMDAX Bending Machine makes the entire bending operation smarter, cleaner, and more integrated into a modern, data driven factory.

Why ARMDAX Automatic Bending Machine Are the Global Choice

ARMDAX has become a focal point for sheet metal factories worldwide looking to upgrade. Our machines are not just equipment; they are productivity transformation partners.

Unmatched Technical Advantages:

Extreme Precision & Consistency:

Advanced CNC Control: User-friendly interface allows for complex multi-axis bending with zero guesswork.

Real-Time Angle Correction: Automatic compensation ensures every bend is perfect, regardless of material batch variations.

Revolutionary Efficiency & Speed:

Lightning-Fast Cycle Times: The automatic bending machine drive provides rapid ram movement, drastically increasing parts-per-hour output.

Zero-Second Job Changeover: Save programs for thousands of parts. Switch between jobs in seconds, making small-batch production highly profitable.

Smart Factory Ready:

IoT Connectivity: Optional connectivity for production monitoring, predictive maintenance alerts, and data analytics.

Safety Integrated: Advanced laser guards, light curtains, and intelligent crowning systems ensure a safe working environment.

Sustainable & Cost-Effective:

Dramatically Lower Operating Costs: Save massively on energy and eliminate hydraulic oil costs.

Minimal Downtime: Robust construction and simpler mechanics ensure maximum uptime and a rapid return on investment (ROI).

See the Difference: Explosive Popularity of ARMDAX Video Demonstrations

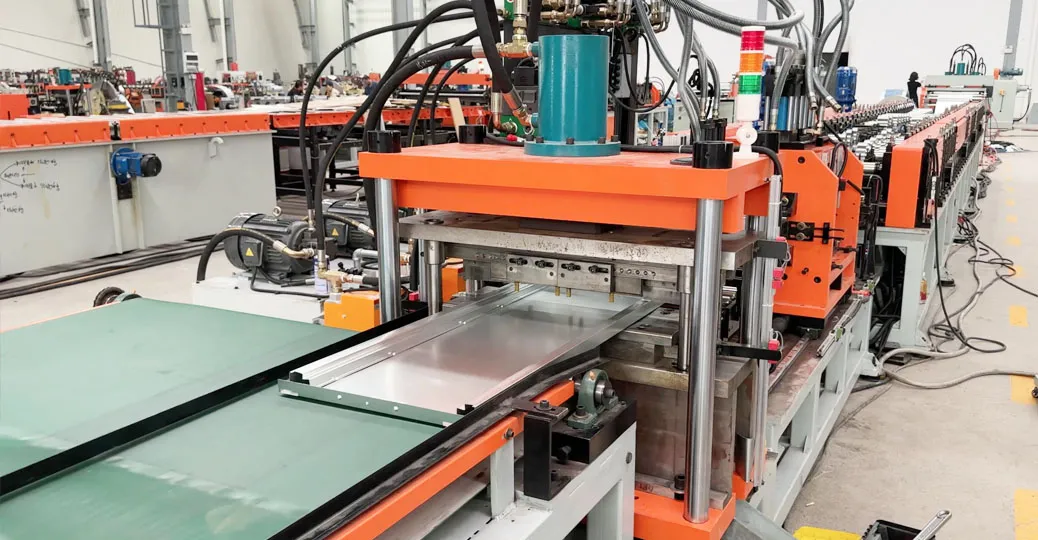

A picture is worth a thousand words, but a video is worth a thousand inquiries. Our detailed factory demonstration videos, showcasing machines effortlessly handling complex bends from coil to finished part have gone viral in the global manufacturing community.

We are receiving a surge of daily inquiries from the United States, Germany, Mexico, Southeast Asia, and the Middle East. Fabricators everywhere are witnessing the ARMDAX advantage: how seamlessly our machines integrate, how quietly they operate, and how consistently they deliver flawless results. This visual proof has made ARMDAX the go-to name for factories serious about improvement.

Is an ARMDAX Bending Machine Right for Your Factory?

If you answer YES to any of the following, it's time to talk to ARMDAX:

Are energy bills eating into your profits?

Do you struggle with inconsistent bend quality or slow job setups?

Are you moving towards high-mix, low-volume production?

Do you want to reduce your shop's environmental footprint and noise?

Is integrating with automation (robotic loading/unloading) a future goal?

Conclusion

The difference between an automatic bender and an electric servo press brake is the difference between mechanization and intelligent automation. In 2025 and beyond, the choice is clear for factories aiming to lead, not just compete.

ARMDAX provides the technology, reliability, and smart features that modern sheet metal factories demand. Don't just buy a machine, invest in a proven solution that is already helping countless factories globally to improve production, maximize efficiency, and secure their competitive future.

Ready to Transform Your Bending Operation?

Watch our explosive demonstration videos and see what the world is talking about. Then, contact the ARMDAX engineering team for a personalized consultation. Let us show you how our automatic panel bender can become the most profitable asset on your factory floor.

Contact ARMDAX today for a free, noobligation quote and a virtual factory tour.

Table of Contents