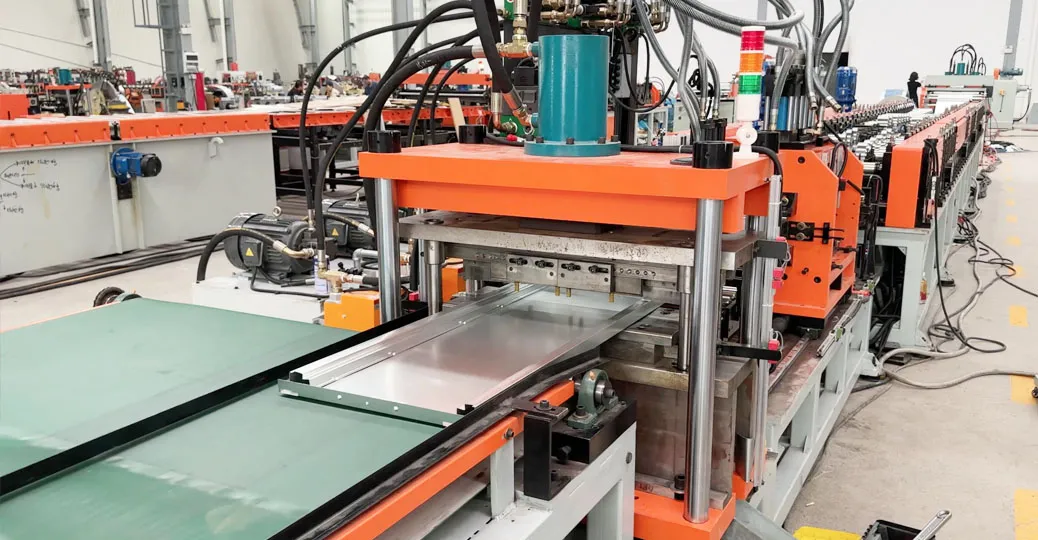

What Factory Should Purchase a Roll Forming Machine?

Oct 10, 2025

Read:239

Source: Armdax

The roll forming machine is a powerhouse of modern manufacturing, but it's not a one-size-fits-all solution. Investing in one is a significant decision, and the key to a high return on investment (ROI) lies in alignment between the machine's capabilities and your factory's specific needs.

So, how do you know if your factory is the right fit? This guide breaks down the types of operations that see the most dramatic transformation from bringing roll forming technology in-house.

1. The High-Volume of The Roll Forming Machine

Is This You? Your factory consumes thousands of meters of the same metal profile every month.

Why It's a Perfect Fit:

Roll forming is the undisputed champion of high-volume, continuous production. If you are constantly ordering standard C-channels, Z-purlins, or shelf posts from external suppliers, an in-house machine will:

Slash raw material costs immediately by switching from pre-formed profiles to raw steel coil.

Eliminate supply chain delays, giving you complete control over your production schedule.

Achieve unparalleled consistency, part after part, mile after mile.

Common Industries: Construction, storage systems, automotive component suppliers.

2. The "Custom Solution" Specialist

Is This You? Your competitive edge comes from creating unique, custom-designed products that can't be bought off the shelf.

Why It's a Perfect Fit:

A roll forming machine is your ultimate tool for innovation. It liberates you from the limitations of standard profiles.

Design Freedom: Create any custom cross-section your clients need, from specialized trim to complex structural components.

Prototype to Production: Quickly and cost-effectively test and produce new profile designs.

Capture Niche Markets: Serve clients with highly specific requirements that your competitors cannot.

Common Industries: Architectural metalwork, specialized furniture, high-tech equipment manufacturing.

3. The Factory Battling Rising Labor Costs and Errors

Is This You? You rely heavily on manual labor for bending or assembling, facing issues with speed, consistency, and rising wages.

Why It's a Perfect Fit:

Roll forming is a leap forward in automation. A single, semi-automated line can replace multiple manual stations.

Reduce Labor Dependency: One operator can manage the entire forming process.

Eliminate Human Error: Achieve perfect dimensional accuracy on every piece, drastically reducing scrap and rework.

Boost Overall Throughput: Produce more with the same or fewer resources.

Common Industries: Any metal fabrication shop looking to scale and systematize its production.

4. The Integrated Manufacturer Seeking Vertical Integration

Is This You? You want to control more of your supply chain to improve margins, quality, and security.

Why It's a Perfect Fit:

Bringing roll forming in-house is a classic and powerful move for vertical integration.

Control Your Destiny: No more being at the mercy of your profile supplier's price hikes or delivery delays.

Improve Profit Margins: Capture the profit that was previously going to your roll forming supplier.

Ensure Quality from Start to Finish: Guarantee the quality of a critical component from the very beginning of your production process.

5. The Growth-Focused Business with Expansion Plans

Is This You? You have a clear vision for growth and are investing in equipment that will scale with you.

Why It's a Perfect Fit:

A modern roll forming system is a scalable asset.

Future-Proof Your Investment: Many machines are designed with modularity in mind, allowing for future upgrades (e.g., adding a pre-punching station).

Handle Increased Demand: The high-speed nature of roll forming means your capacity can grow significantly without a proportional increase in floor space or labor.

Is Your Factory Ready? A Quick Checklist

Answer "Yes" to these questions, and a roll forming machine is likely an excellent investment:

Do we use a high volume of linear metal profiles?

Are we dissatisfied with our current supplier's cost, quality, or lead times?

Do we need custom profiles to stay competitive?

Are labor costs and inconsistencies eating into our profits?

Do we have a stable demand that justifies the initial investment?

So purchasing a roll forming machine isn't just about buying a piece of equipment; it's about making a strategic decision to enhance control, efficiency, and profitability.

The right factories are those that see metal profiles not just as a component, but as the very backbone of their product. If your factory falls into one of the categories above, the question isn't "Should we buy one?" but "How quickly can we implement one?"

Still Not Sure If Your Factory is the Right Fit?

You don't have to figure it out alone. Contact our experts at Armdax for a free, confidential consultation. We'll analyze your specific production needs and help you calculate the potential ROI of a roll forming machine for your business.

Click here to schedule your free consultation today!

Table of Contents