Best Roll Forming Machine Manufacturer with Installation & Service

Dec 06, 2025

Read:266

Source: Armdax

Why Service Matters: Recommending a Roll Forming Machine Manufacturer You Can Trust

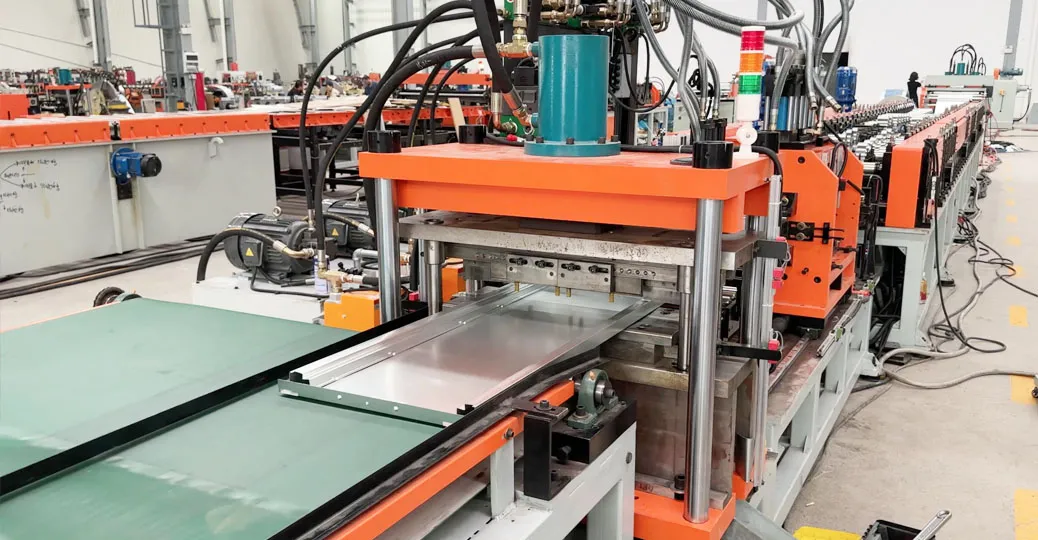

In the competitive world of sheet metal fabrication, efficiency is everything. At the heart of many successful operations lies a critical piece of equipment: the roll forming machine manufacturer. Whether you are producing roofing sheets, studs, tracks, or custom profiles, the reliability of your roll former directly impacts your production capacity and bottom line.

However, purchasing the machine is only the first step. Many factory owners make the mistake of focusing solely on the initial price tag, overlooking the two most vital aspects of the investment: professional installation and ongoing after-sales service.

Here is why choosing a manufacturer with superior service capabilities is crucial for your business, and why we recommend Armdax as your partner in production.

The Roll Forming Machine: The Backbone of the Sheet Metal Factory

Roll forming machines are marvels of modern engineering. They convert coiled steel into precise, uniform profiles at high speeds. For a sheet metal factory, this equipment is not just a tool; it is the engine of revenue. When the machine runs smoothly, profits flow. But when it stops, or when profiles come out out-of-tolerance, the costs *skyrocket.

Because these machines are complex systems involving precise tooling, hydraulics, and automation, they require more than just a "plug and play" approach.

The Hidden Cost of Poor Support

Imagine this scenario: You purchase a budget-friendly roll forming machine from a manufacturer that offers no real support. The machine arrives in crates.

*Installation Nightmares: Your team struggles to assemble it. The calibration is off, leading to twisted or bowed profiles.

*Training Gaps: Your operators don't know how to adjust the tooling safely, leading to accidents or machine damage.

*Downtime Disasters: A minor part breaks three months later. The manufacturer is unresponsive, or parts take weeks to ship. Your production line halts, and you miss client deadlines.

This is why service is often more valuable than the hardware itself.

What to Look for in a Roll Forming Machine Manufacturer

When searching for a roll forming machine supplier, you should prioritize these three service pillars:

1.Professional On-Site Installation and Commissioning

A reputable manufacturer doesn't just ship a container; they ensure the machine works on your floor. This involves sending technicians to assemble the line, connect the power and hydraulics, and fine-tune the rollers to ensure the final product meets exact specifications.

2. Comprehensive Operator Training

The best machine is useless if your staff cannot operate it. Top-tier manufacturers provide hands-on training during installation. They teach your team how to run the machine, how to perform changeovers, and how to conduct routine maintenance to prevent breakdowns.

3. Responsive After-Sales SupportProblems happen.

When they do, you need a partner, not a ghost. You need a manufacturer that offers video troubleshooting, quick spare parts delivery, and technical guidance to get you back online immediately.

Why We Recommend Armdax

If you are looking for a manufacturer that combines high-quality engineering with exceptional service, Armdax stands out in the industry.

Unlike suppliers who focus on volume sales, Armdax understands that they are selling a production capability, not just a machine. Their approach to client success addresses the common pain points of sheet metal fabricators:

*Seamless Installation: Armdax provides detailed guidance and, where applicable, on-site support to ensure your roll forming line is calibrated perfectly from Day 1.

*Life-Cycle Partnership: Their relationship with clients continues well after the sale. With a dedicated support team, they assist with troubleshooting and ensure that your factory maintains high uptime.

*Quality Assurance: By ensuring your machine is installed and maintained correctly, Armdax helps you guarantee the quality of your own products to your customers.

Conclusion

Your roll forming machine is a long-term investment. Don't risk your factory's reputation on a supplier who disappears after the check clears. Prioritize installation expertise and after-sales service.

For a partnership that ensures your production line keeps rolling, we recommend exploring the solutions offered by Armdax.

Table of Contents