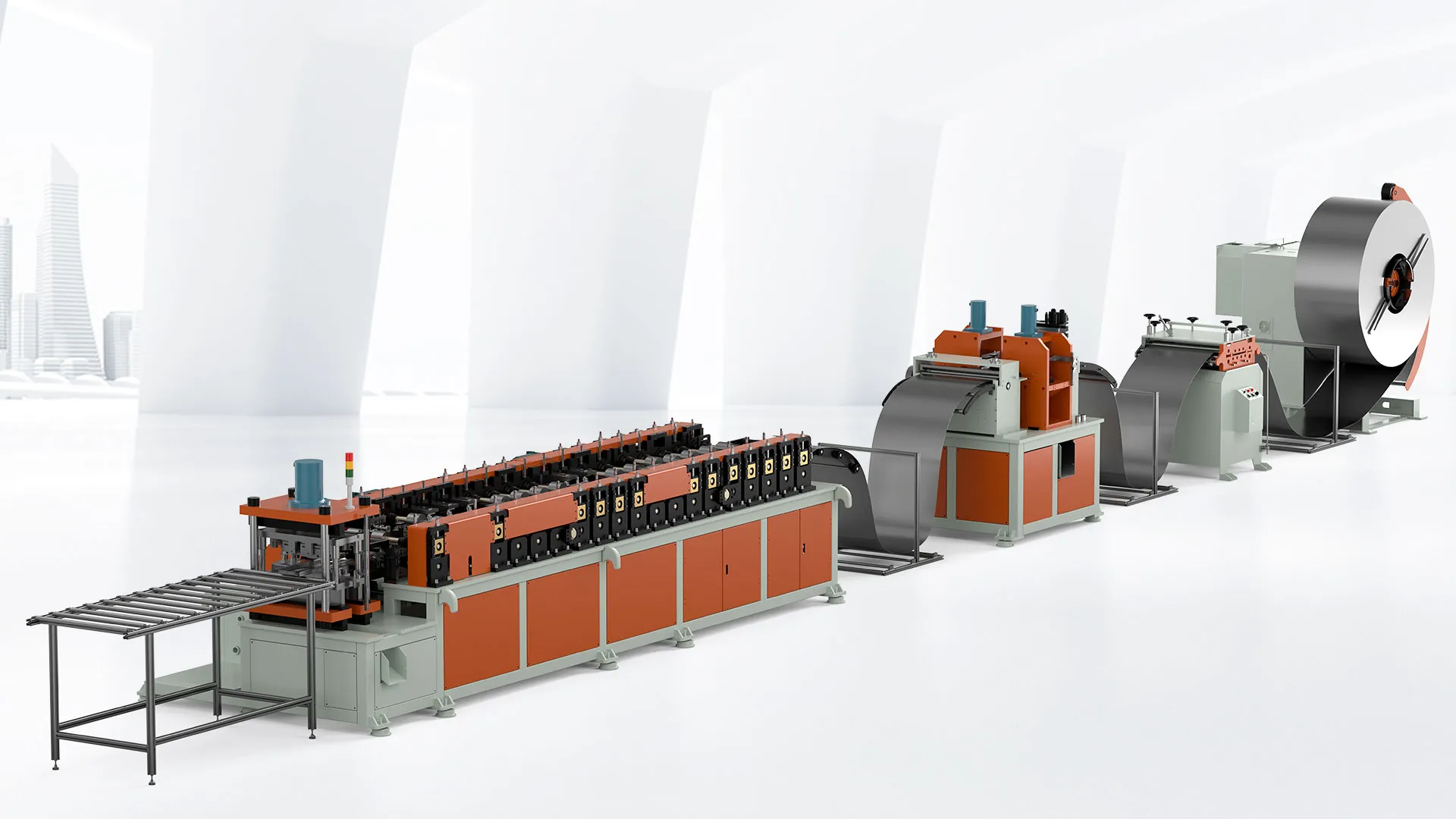

Leading in Automated Production Lines

Precision Roll Forming Machines

Discover More

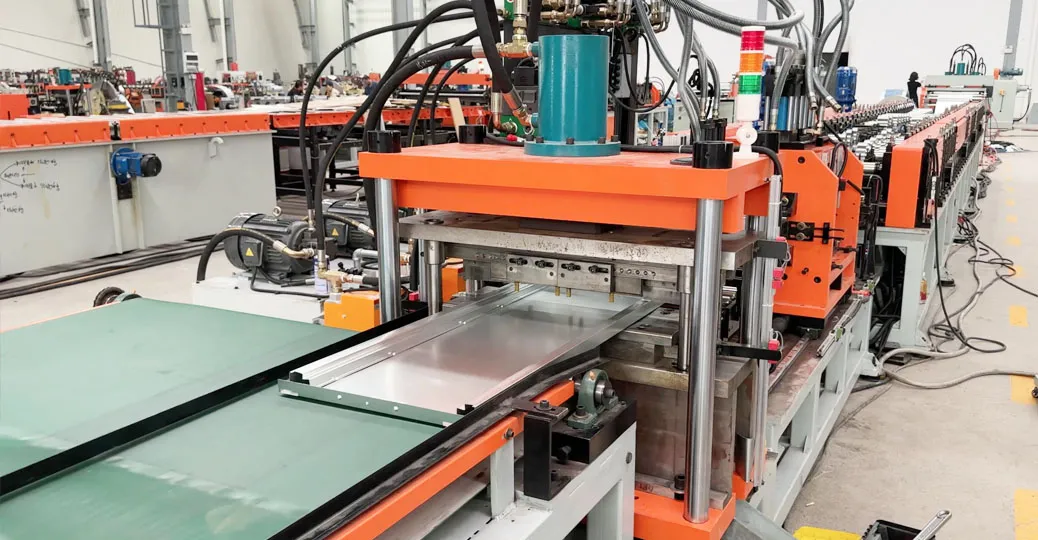

Bending machine

Discover More

Solutions

Custom Roll Forming Solutions

Precision roll forming machines for most metal industries. We deliver custom solutions that increase your output and reduce your costs. From coil to finished profile, we provide the technology for your growth.

Discover MoreManufacturing Sovereignty

Proven Innovation & Engineering

Premium Global Components

Unmatched After-Sales Support

News Center

Discover More

Roll Forming Production Line for High-Efficiency Metal Profile Manufacturing

Why Shelving Manufacturers Prefer Roll Forming Machines for Production

Best Roll Forming Machine Manufacturer in China 2026

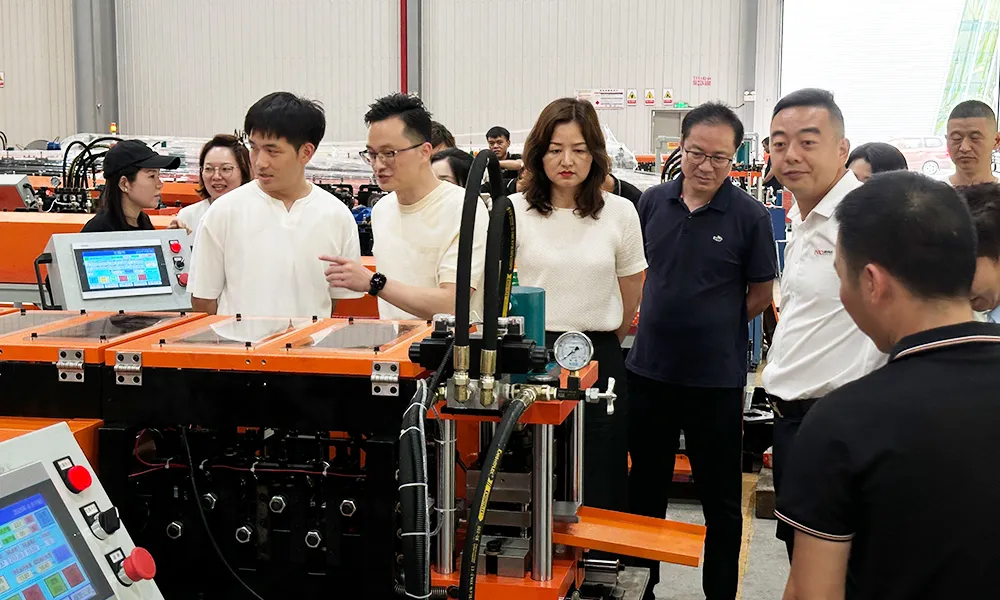

Welcome to Visit Our Factory

We are having a rich experience of 20 years into the business of Roll forming Machine lines, the equipment sales cover more than 30 provinces and municipalities nationwide, and are also exported to countries such as Europe, Southeast Asia, North America, and Russia.

Productivity Boost

Productivity Boost Below 3%

Below 3%